Manual Pallet Racking System

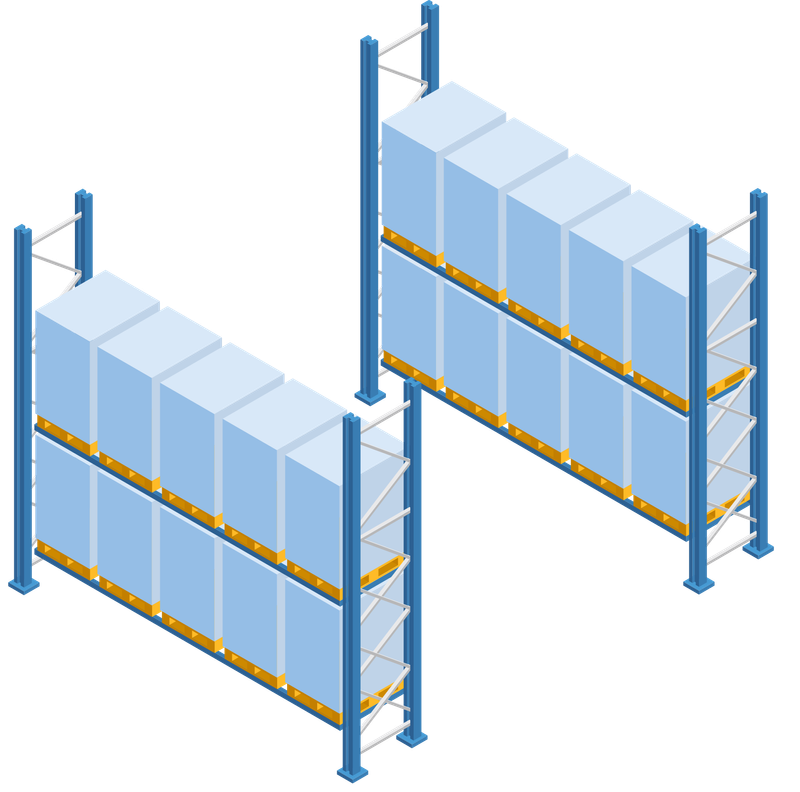

Pallet Racking Structure

Pallet racking is a specialized storage solution often used in industrial and commercial environments. It is a racking system designed specifically for the storage of pallets. Pallet racking consists of vertical uprights, cross beams, and supports which form a robust and stable structure. The pallets are placed horizontally on the cross beams, with the uprights providing vertical support. Depending on requirements, pallet racking can be configured in different heights, widths, and depths to make the best use of available space. They can also be fitted with various additional features, such as push-through guards or mesh back panels, to increase the safety and stability of the system.

Manual Pallet Racking System - Solves the following Problems!

Select one of the problems. You will receive instructions that you can use to calculate optimization potential.Low Storage Space Utilization

Damaged Goods

Low Ceiling Height

Low Available Storage Space

Large Quantities of Single-Grade Pallets

Manoeuvring Efforts

Slow-Moving Parts (C-Parts/Spare Parts)

Waiting for Replenishment

Manual Pallet Racking System - Find the Right Offering for You

Select products and receive detailed information. You can use the platform to contact product suppliersManual Pallet Racking System - The Solution can be Combined with the Following Solutions

Here you can find solutions, which can be combined with the presented solution.Manual Pallet Racking System - The Following Solutions can also Solve the Pain Point

Here you can find other solutions, which are suitable for the optimization of the pain points (Low Storage Space Utilization) as well as variants of the current solution.

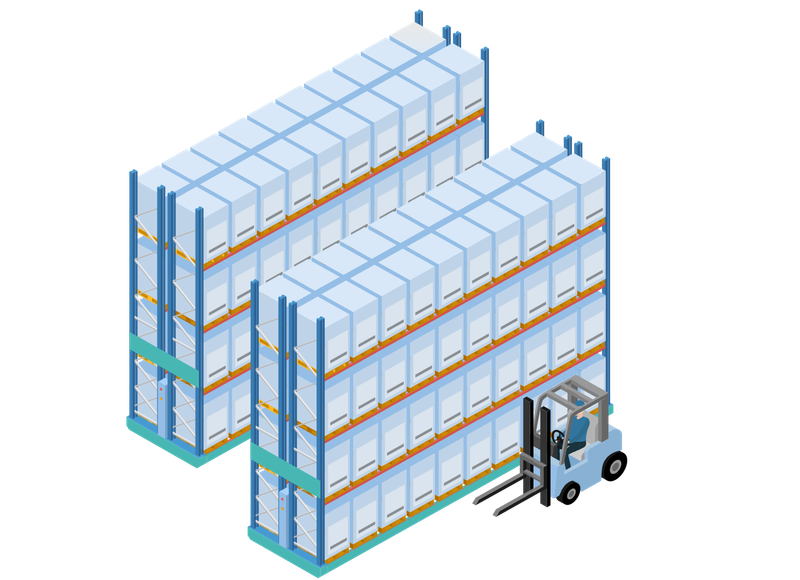

Manual High-Bay Racking

- Storage at a height of up to 15 meters

- Operation of the warehouse by forklift trucks

- High flexibility with variable article structure

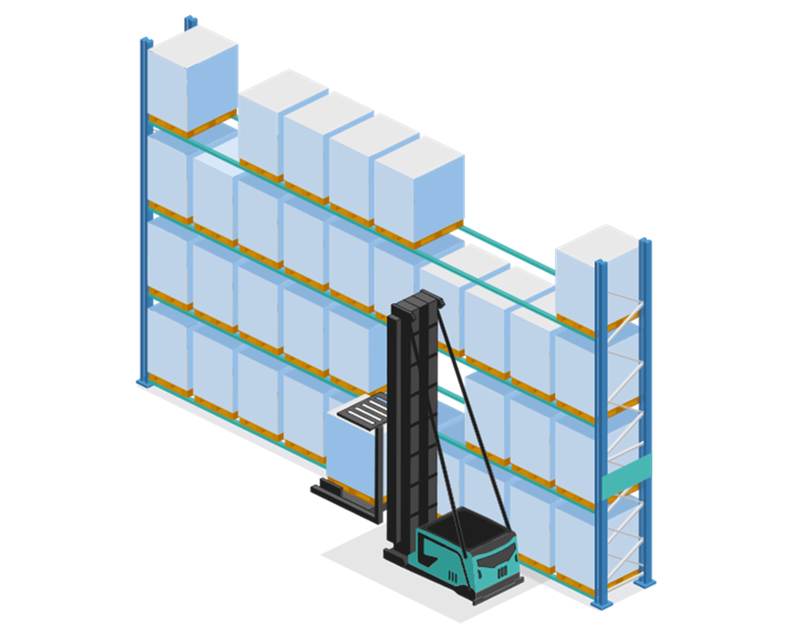

Rider High Lift Stacker

- Ergonomic and time-saving, especially for long distances

- Combination of lifting and driving for efficient pallet handling

- Suitable for a medium lifting height

Very Narrow Aisle Truck

- Low aisle width required, enabling high storage density

- Variants available for storage and retrieval, and picking

- Access to high-level storage locations possible

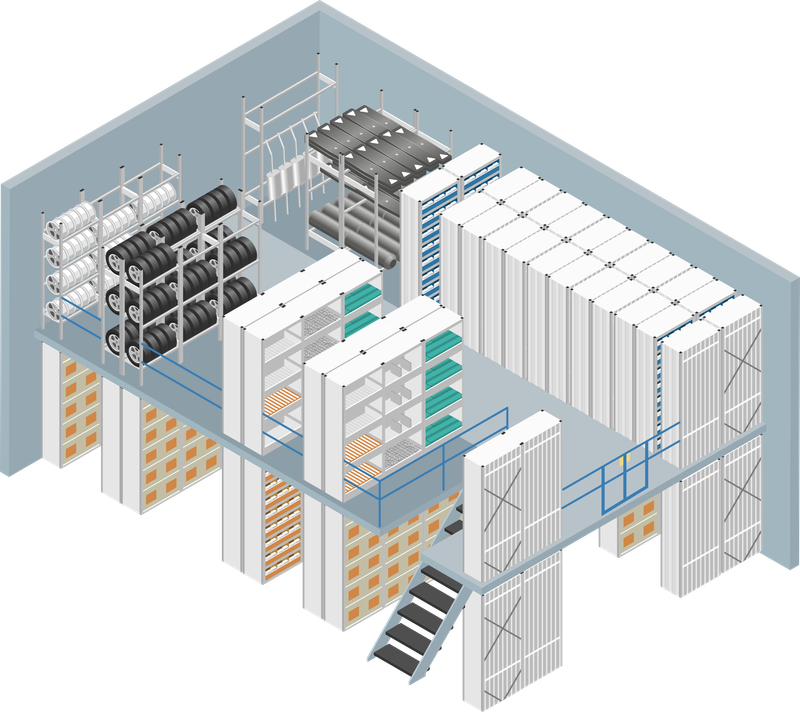

Mezzanine warehouse

- Efficient use of space in warehouses with high ceilings

- Cost savings when expanding storage capacity

- Versatile use possible

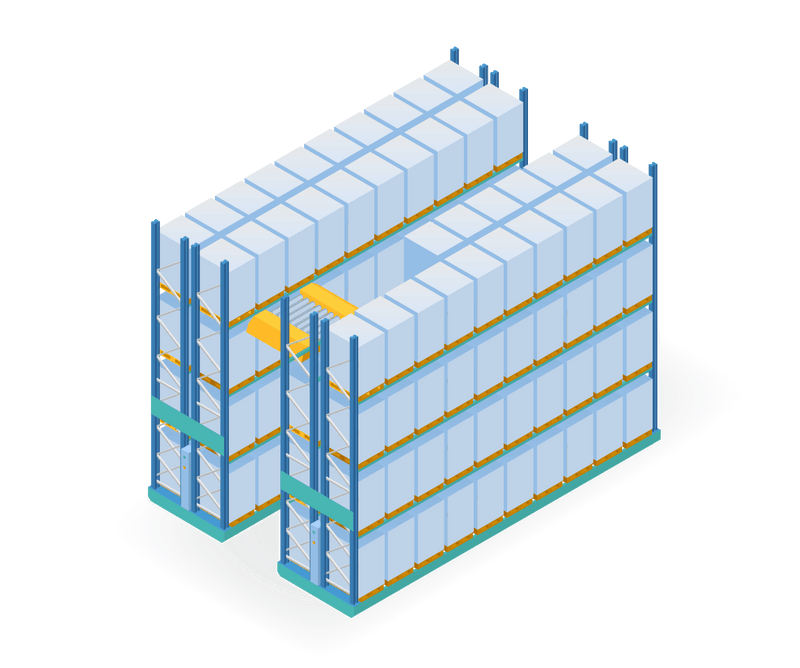

Shuttle System - Large Loads

- Suitable for many pallets per article type

- Intensive rotation of homogeneous article types

- Increased storage density

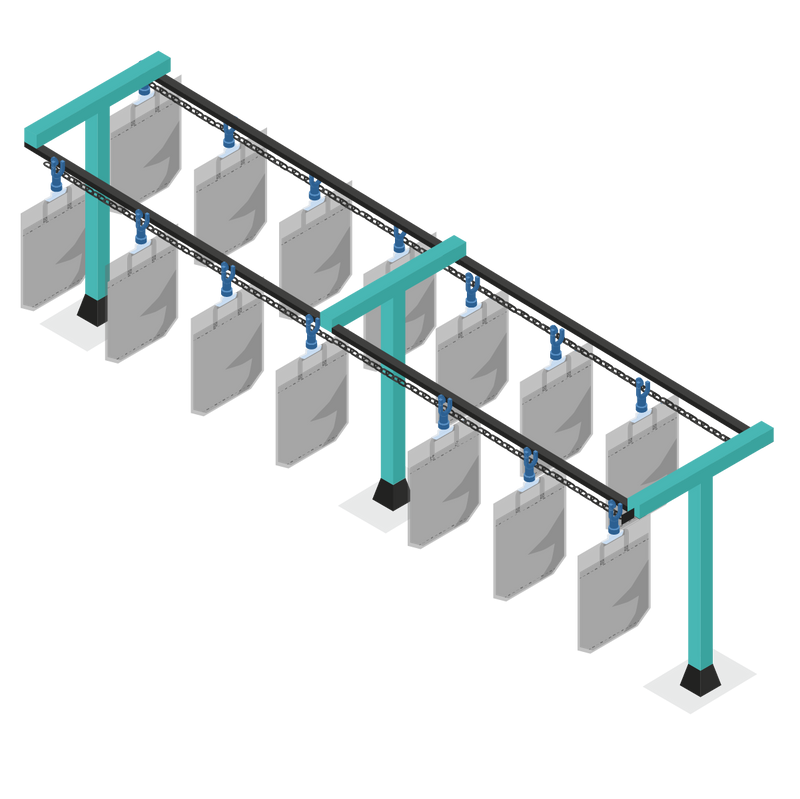

Pocket sorter – Adapter systems

- Optimal use of space

- Gentle transport

- Dynamic buffering

-800x700.png)