Keenon +300kg heavy-load robot with lift function - S300

Keenon +300kg heavy-load robot with lift function - S300

Price from

16,800 € (plus VAT, instruction and...

Primary load carrier

Euro pallet

Secondary load carrier

Cartons

Max. dimensions primary load carrier (L)

925 mm

Max. dimensions primary load carrier (W)

620 mm

Max. dimensions primary load carrier (H)

1,282 mm

Keenon +100kg heavy-load robot - S100

Keenon +100kg heavy-load robot - S100

Price from

15,300 € (plus VAT, instruction- and...

Primary load carrier

Euro pallet

Secondary load carrier

Cartons

Max. dimensions primary load carrier (L)

925 mm

Max. dimensions primary load carrier (W)

620 mm

Max. dimensions primary load carrier (H)

1,282 mm

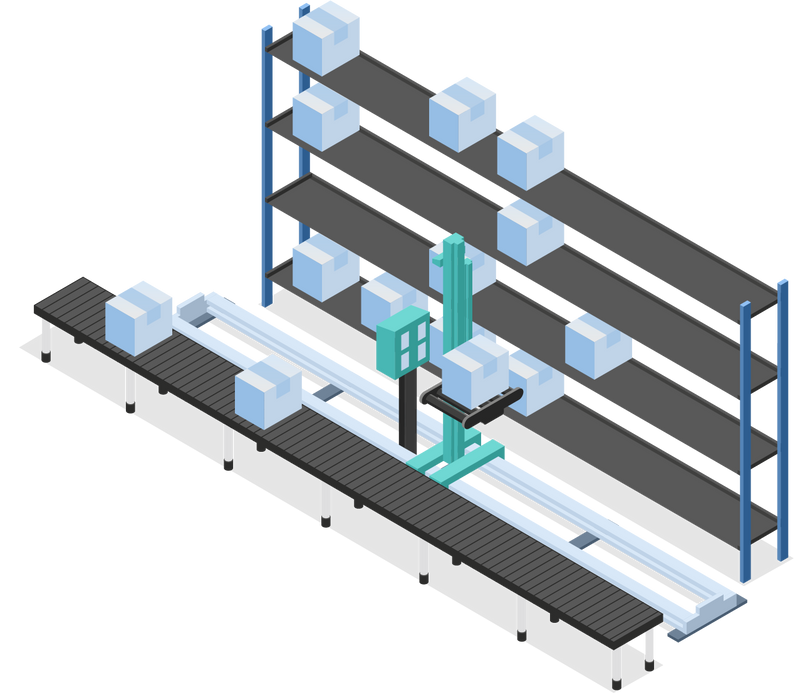

BITO LEO carrier

BITO LEO carrier

Price from

17,000 €

Primary load carrier

Bins & Containers

Secondary load carrier

Cartons, Trays, Article (unpacked)

Max. dimensions primary load carrier (L)

600 mm

Max. dimensions primary load carrier (W)

400 mm

Max. dimensions primary load carrier (H)

250 mm

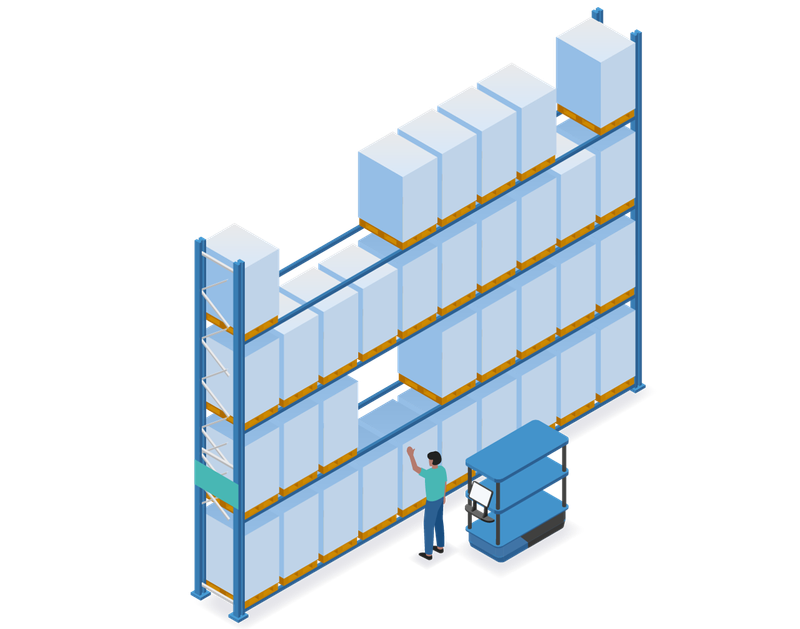

Locus Origin

Locus Origin

Price from

On request

Primary load carrier

Container

Secondary load carrier

Cartons, Article (unpacked)

Max. dimensions primary load carrier (L)

n/a

Max. dimensions primary load carrier (W)

n/a

Max. dimensions primary load carrier (H)

n/a

Chuck

Chuck

Price from

650,000 $ (base 8-unit solution)

Primary load carrier

Bins & Containers

Secondary load carrier

Cartons, Article (unpacked)

Max. dimensions primary load carrier (L)

914 mm

Max. dimensions primary load carrier (W)

750 mm

Max. dimensions primary load carrier (H)

1,600 mm

-800x700.png)