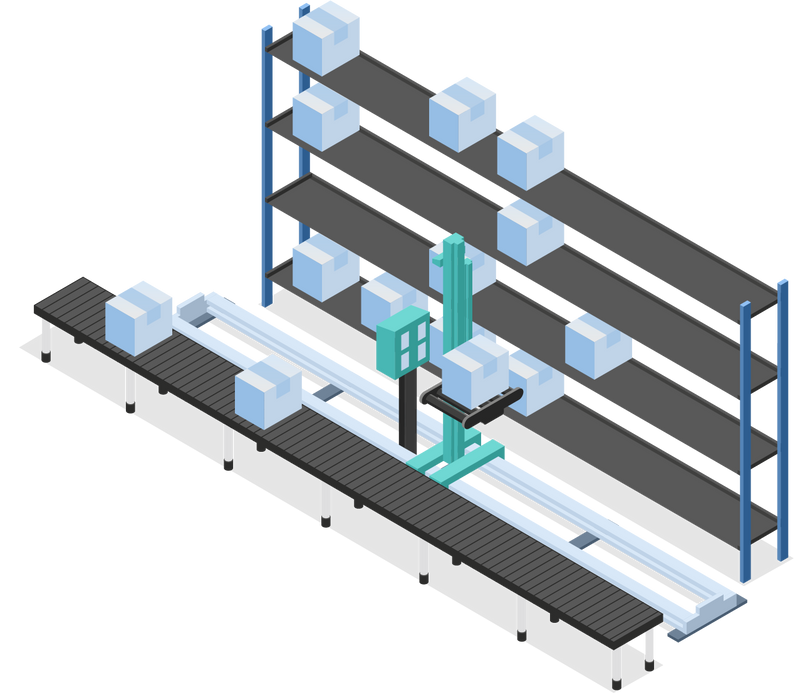

Horizontal Order Picker

Efficient Order Picking at Floor Level: The Horizontal Order Picker at a glance

A horizontal order picker is an industrial truck that has been specially developed for picking goods at floor level or in low racking levels. In contrast to high lift order pickers, which move upwards, the horizontal order picker only moves through the warehouse aisles at floor level. The operator stands on a traveling platform and picks items directly from the shelves to place them on a pallet or roll container. Typical areas of application are distribution centers, dispatch warehouses and retail logistics, where many items need to be put together quickly and efficiently. Technically, horizontal order pickers are characterized by long forks (often for several load units), powerful drive batteries, an ergonomic driver platform and precise control systems. Some models also offer an automatic following system in which the vehicle follows the operator independently and stops automatically at the optimum picking position - this reduces walking distances and significantly increases efficiency.

Horizontal Order Picker - Solves the following Problems!

Select one of the problems. You will receive instructions that you can use to calculate optimization potential.Long walking distances

Many Bending Movements (Quantity)

Short Distances between Picks

Frequent Aisle Repetitions

Entering and Exiting of Vehicles

Long Transport Distances

Regularly Changing Paths

Long driving distances

Horizontal Order Picker - Find the Right Offering for You

Select products and receive detailed information. You can use the platform to contact product suppliersHorizontal Order Picker - The Solution can be Combined with the Following Solutions

Here you can find solutions, which can be combined with the presented solution.

Automatic Following System

- Maintain operational flexibility

- Reduction of unproductive walking time, e.g. due to getting on and off vehicles

- Both autonomous following of the picker and driving possible

Asset Management

- Tracking of inventory

- Management of multiple types of assets

- Maintenance management

Horizontal Order Picker - The Following Solutions can also Solve the Pain Point

Here you can find other solutions, which are suitable for the optimization of the pain points (Long walking distances) as well as variants of the current solution.

Pedestrian Pallet Truck

- Pallet truck with electric drive and escort on foot

- Effort-saving and ergonomic pallet truck variant

- Flexible application options in intralogistics

Rider High Lift Stacker

- Ergonomic and time-saving, especially for long distances

- Combination of lifting and driving for efficient pallet handling

- Suitable for a medium lifting height

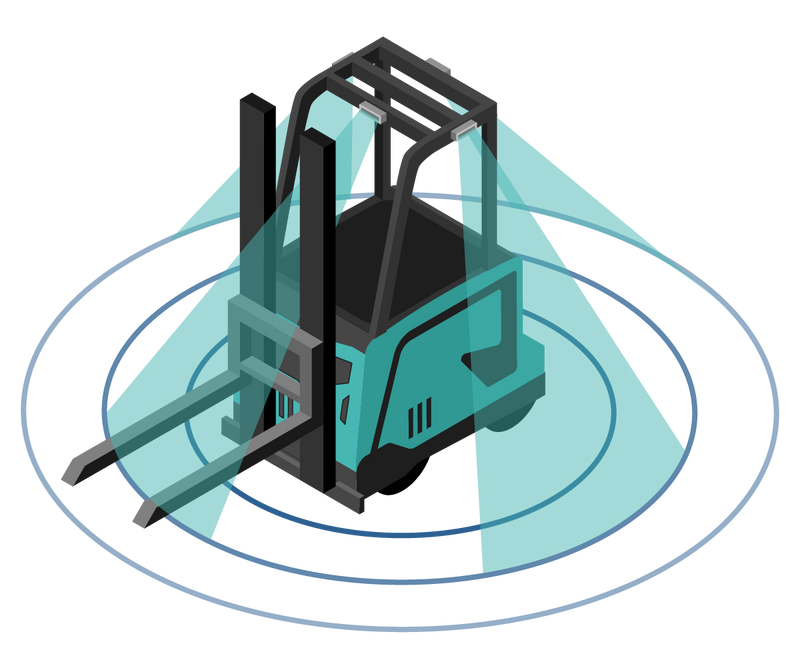

Forklift Truck – Autonomous

- Increased efficiency through continuous workflows

- Cost savings due to reduced personnel requirements

- Increased safety thanks to sensors

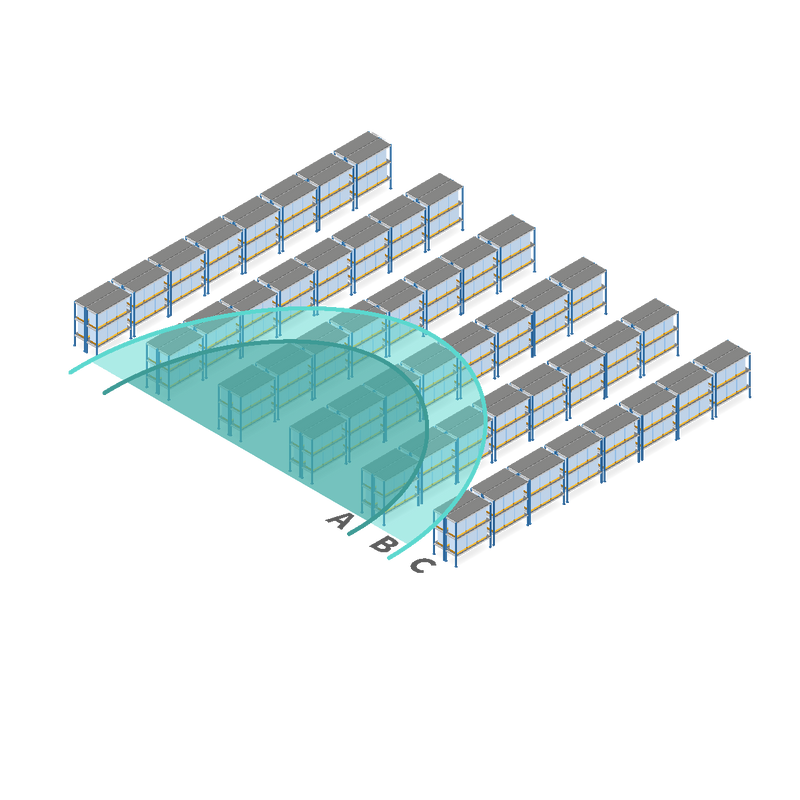

ABC zoning in the radius system

- Distribution of articles according to access frequency

- Reduces walking time and congestion

- Prioritizes inventory

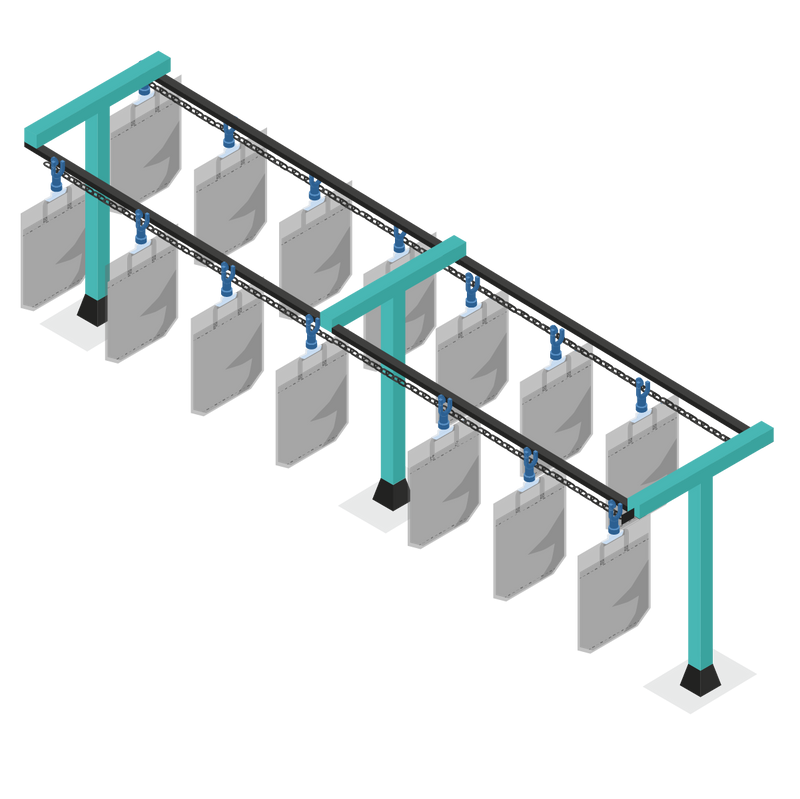

Pocket sorter – Adapter systems

- Optimal use of space

- Gentle transport

- Dynamic buffering

Additional Storage Spaces for Fast Movers

- Reduction of waiting times due to congestion

- Reduction of walking distances

- Optimization of the material flow

-800x800.png)

-800x800.png)

-800x700.png)