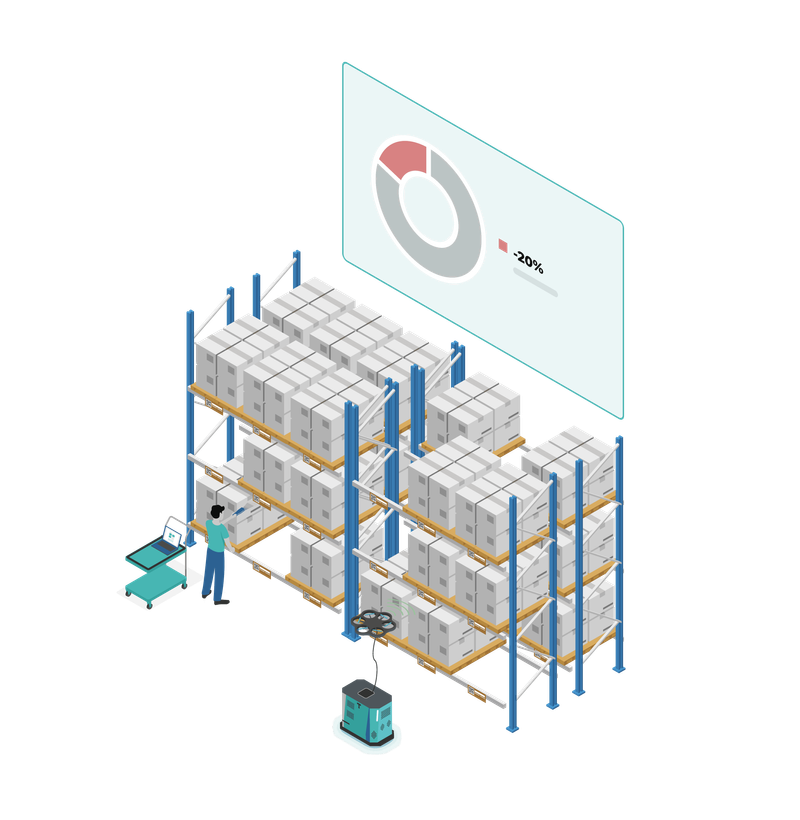

OX-Distance Sensor

Automatic real-time storage position detection – for greater transparency and efficiency in the warehouse.

OX-Distance Sensor

Price from

On request

Application reasons

Automate replenishment processes...

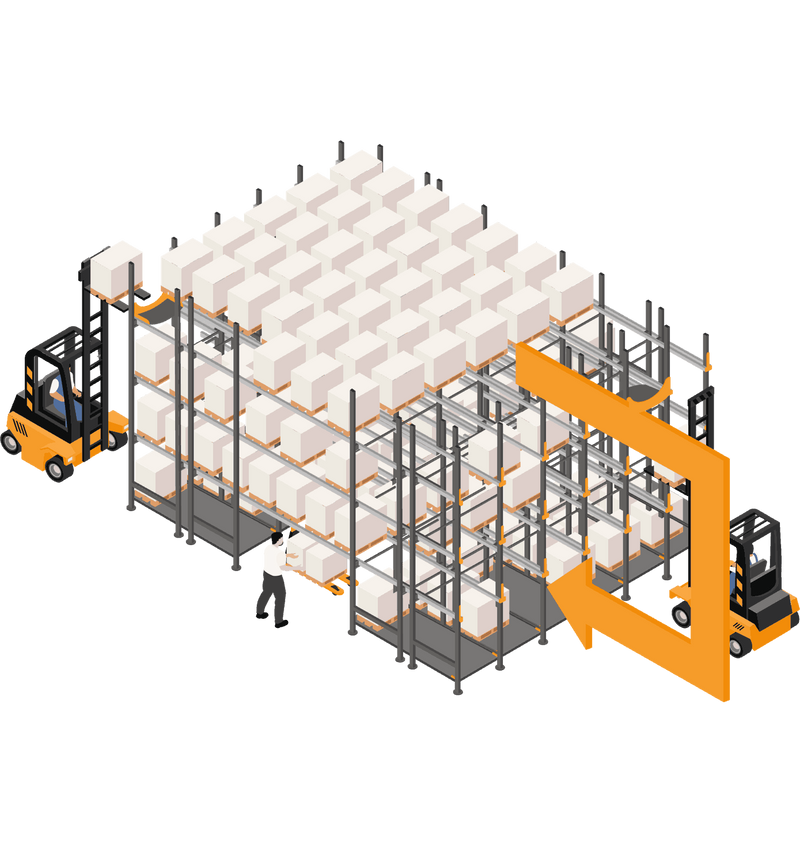

Suitable for the following types of storage

Shelf storage, Floor storage, Block...

Suitable for the following storage structure

Fixed storage spaces

Technology used

Distance sensors (TOF, ultrasound, etc...

Place of attachment

Ceiling, Shelf, Walls or beams, Mobile...

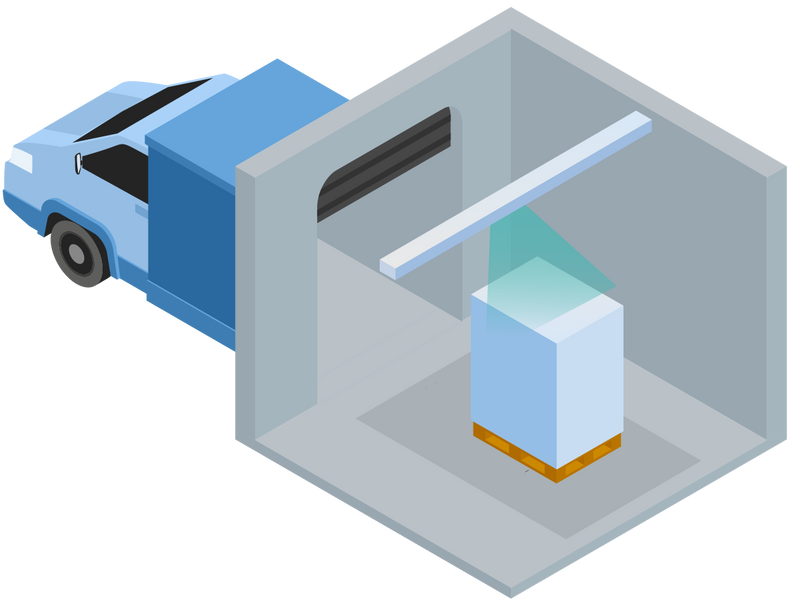

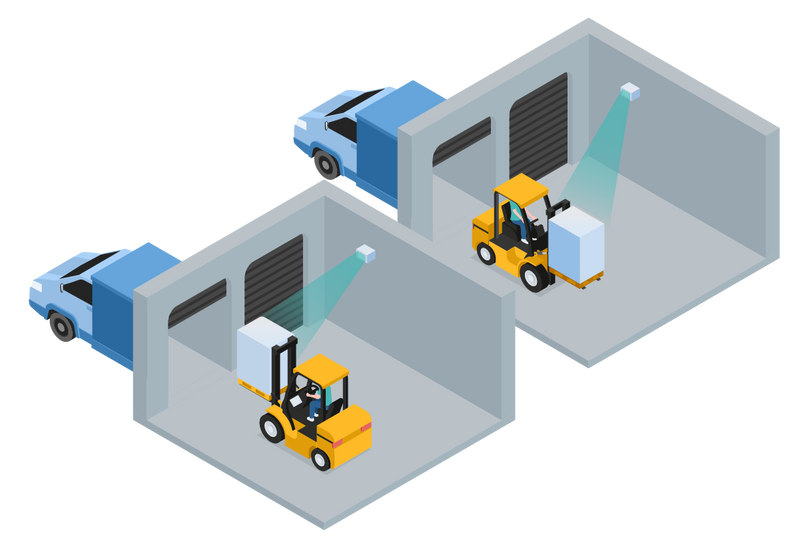

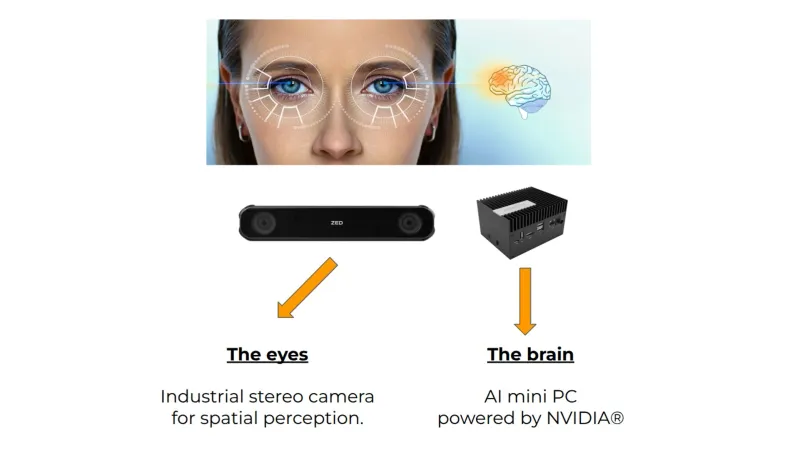

Digivision for AGVs

Digivision for AGVs: Give your AGVs eyes

Digivision for AGVs

Price from

On request

Application reasons

Increase transparency, Minimize error...

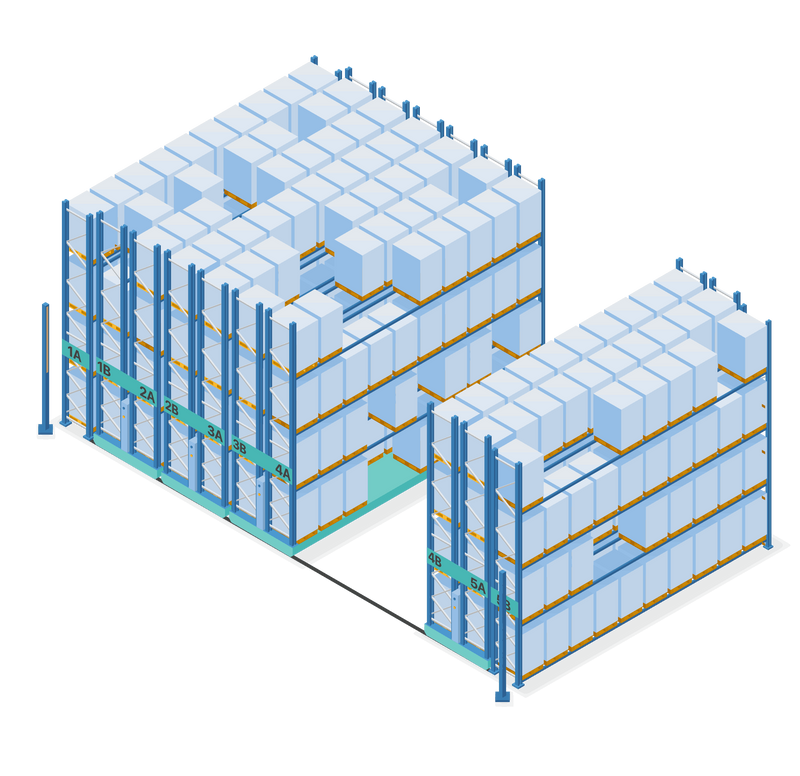

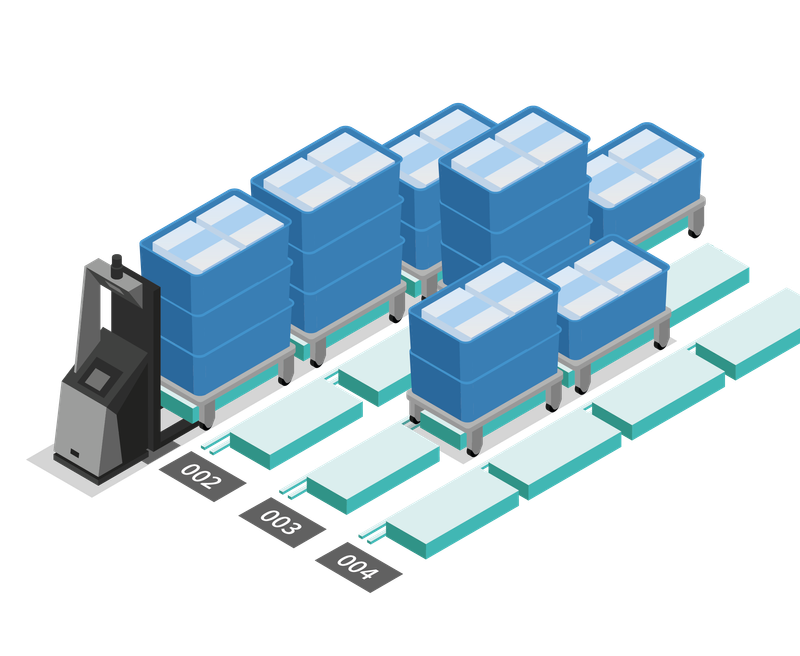

Suitable for the following types of storage

Floor storage, Block storage, Flow racks

Suitable for the following storage structure

Fixed and dynamic assignment

Technology used

Camera system with AI

Place of attachment

Ceiling, Others (Directly at the AGV)

-800x800.png)

-800x800.png)