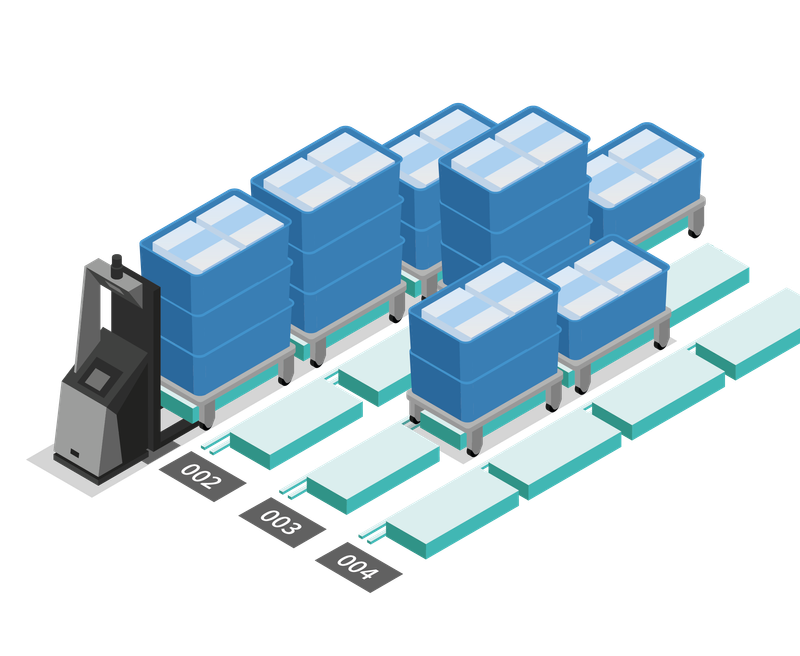

Monomover 2.0

Automated feed for floor rollers in the FiFo station - for a continuous, efficient material flow.

Monomover 2.0

Price from

Price on demand

Primary load carrier

Primary load carriers are floor rollers

Number of storage spaces (primary load carriers)

1 (Each MONOMOVER 2.0 has space for one...

Max. weight utilization per storage space

300 kg

Max. technical performance

660 units/h (With a length of 60 cm per...

System depth

0.19 m

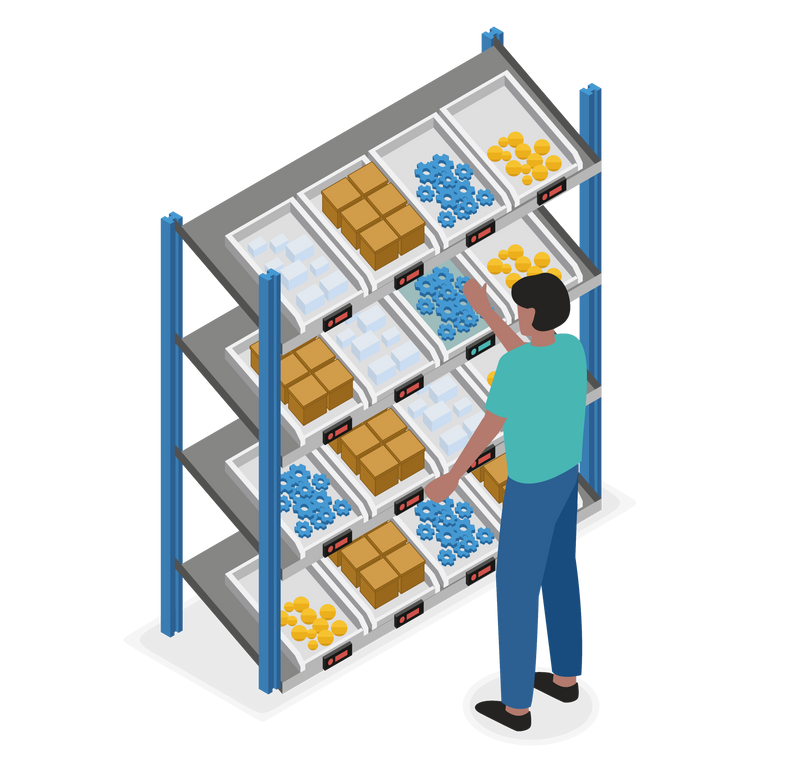

OX-Label Waiting for Replenishment

The highly visible digital signal for smooth and on-time replenishment processes – directly at the picking location, exactly where it is needed.

OX-Label Waiting for Replenishment

Price from

On request

Primary load carrier

Euro pallet, Industrial pallet, Lattice...

Number of storage spaces (primary load carriers)

1 (Pro Einheit ist empfohlen ein OX...

Max. weight utilization per storage space

Weight utilization has no influence on...

Max. technical performance

A request for replenishment is sent at...

System depth

0.014 m