Resource Distribution Strategy

Possible Types of Inefficiencies

Efficient distribution of auxiliary equipment can increase efficiency in the warehouse or in production and reduce waiting times. Auxiliaries are, for example, printers, wrapping machines and other devices that support personnel in their daily work.

Resource Distribution Strategy - Solves the following Problems!

Select one of the problems. You will receive instructions that you can use to calculate optimization potential.Long walking distances

Waiting for Auxiliary Equipment

Long Distances to Auxiliary Equipment

Effort for Receiving Goods

Long Distances for Information Intake

Congestion due to Queues

Waiting times (technical or organizational)

Long driving distances

Resource Distribution Strategy - Find the Right Offering for You

Select products and receive detailed information. You can use the platform to contact product suppliersResource Distribution Strategy - The Solution can be Combined with the Following Solutions

Here you can find solutions, which can be combined with the presented solution.Resource Distribution Strategy - The Following Solutions can also Solve the Pain Point

Here you can find other solutions, which are suitable for the optimization of the pain points (Long walking distances) as well as variants of the current solution.

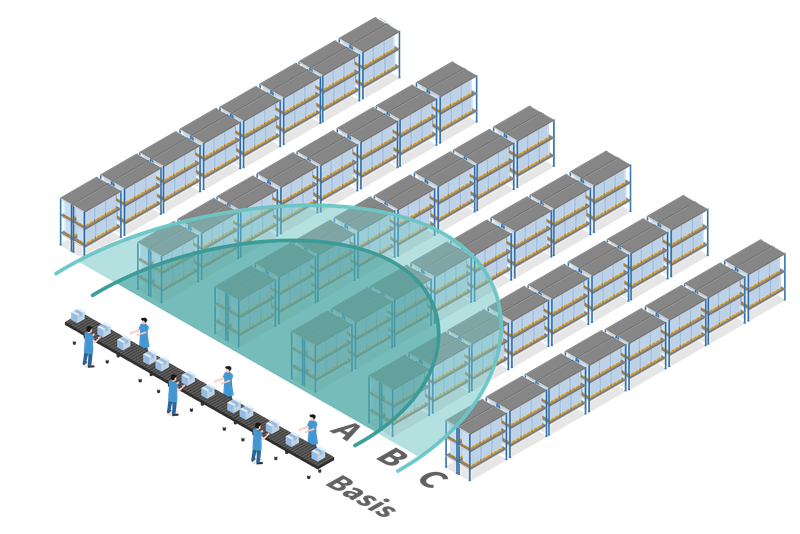

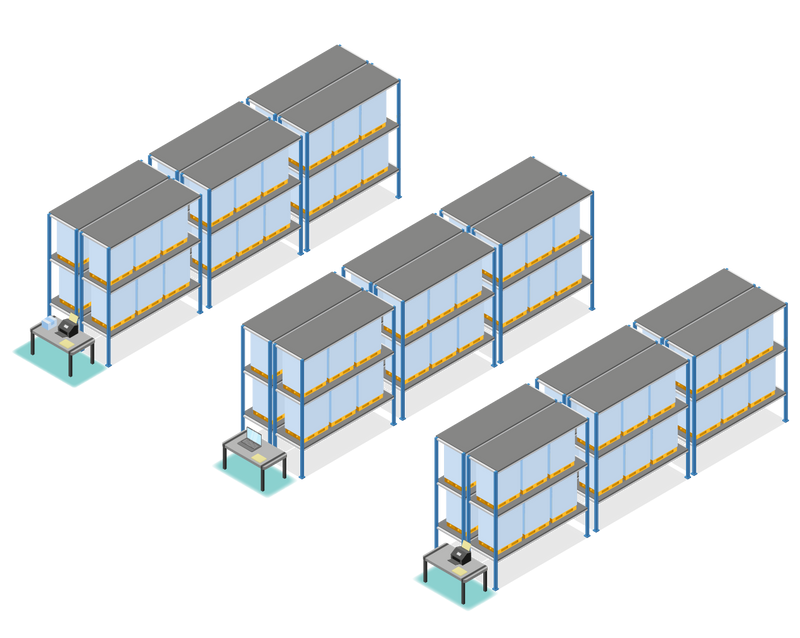

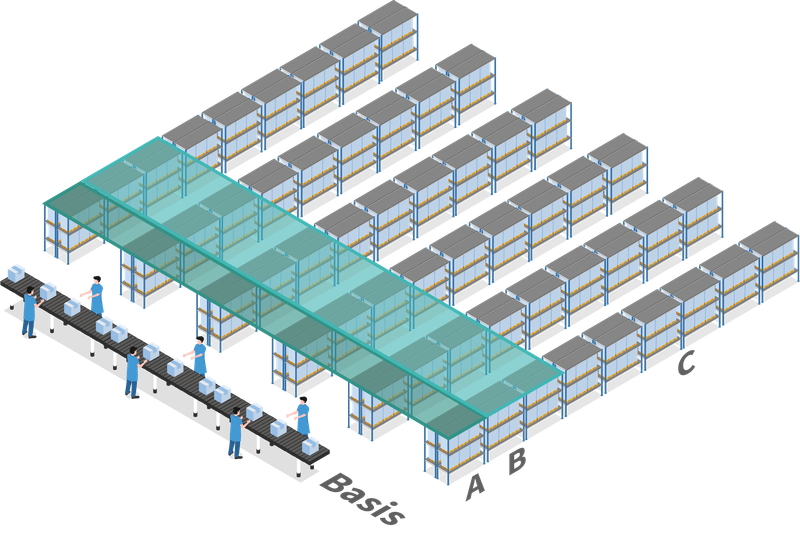

ABC zoning edge-based

- Distribution of articles according to access frequency

- Reduces walking time and congestion

- Prioritizes inventory

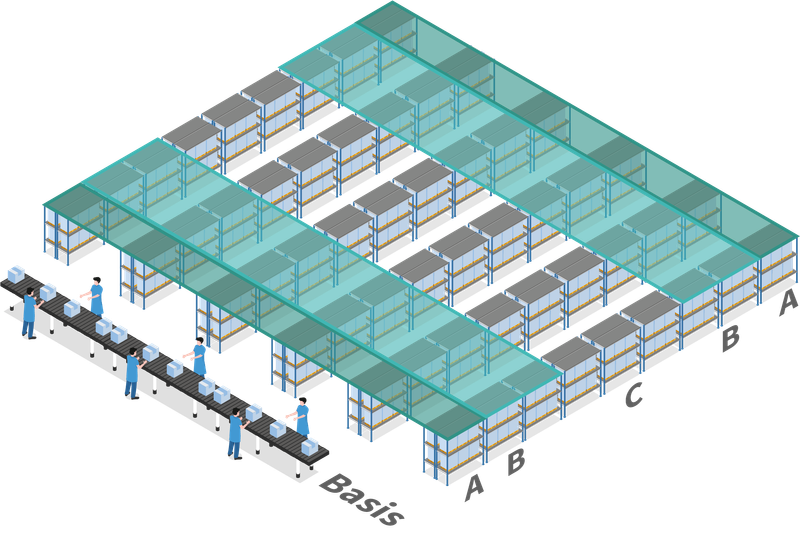

ABC zoning in a segment layout

- Distribution of articles according to access frequency

- Reduces walking time and congestion

- Prioritizes inventory

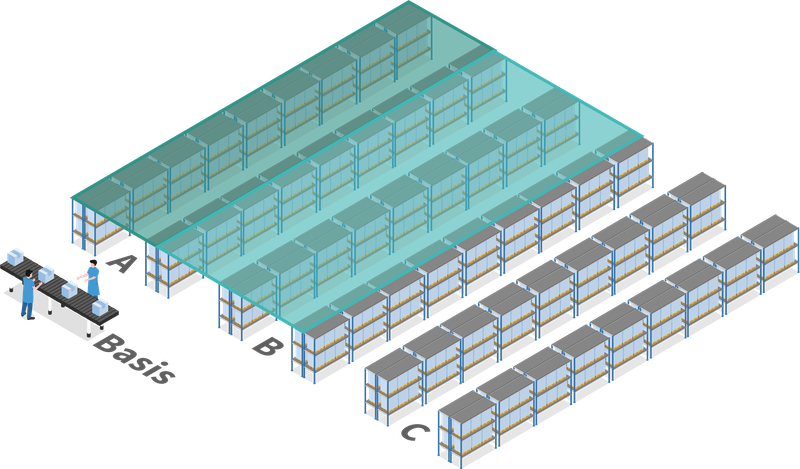

ABC Zoning in a stripe layout

- Distribution of articles according to access frequency

- Reduction of travel times and traffic congestion

- Prioritize inventory

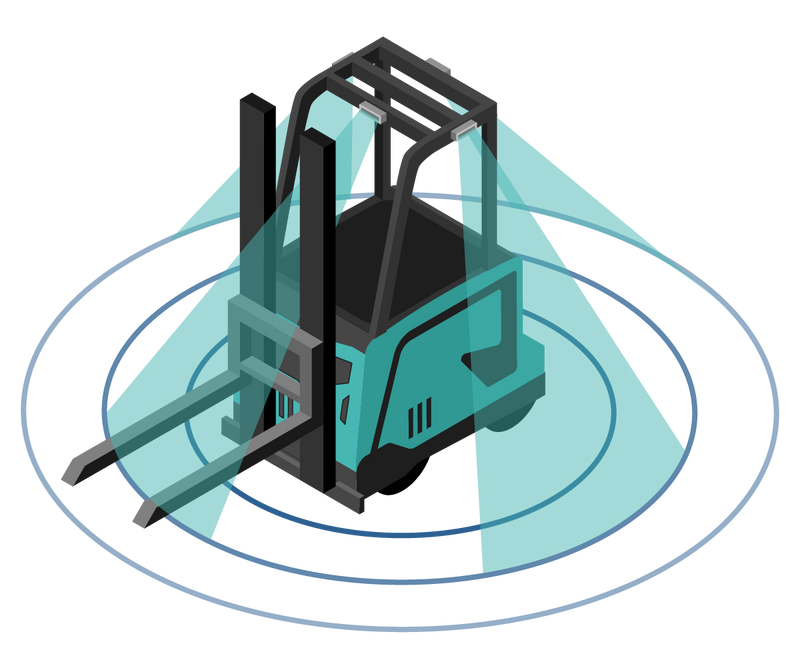

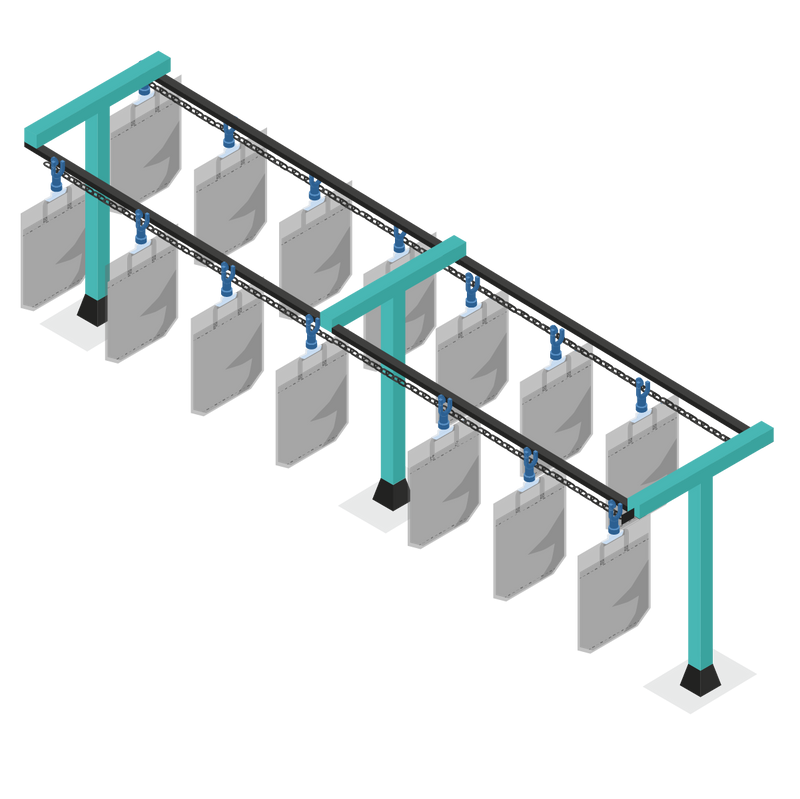

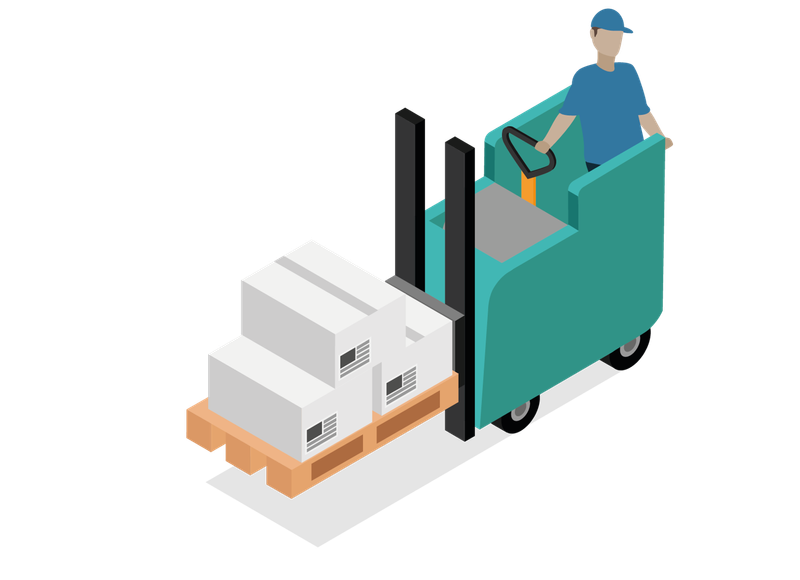

Horizontal Order Picker

- Efficient order picking at floor or low shelf levels

- Ride-on platform and long forks to increase production

- Automatic following system possible

Pedestrian Pallet Truck

- Pallet truck with electric drive and escort on foot

- Effort-saving and ergonomic pallet truck variant

- Flexible application options in intralogistics

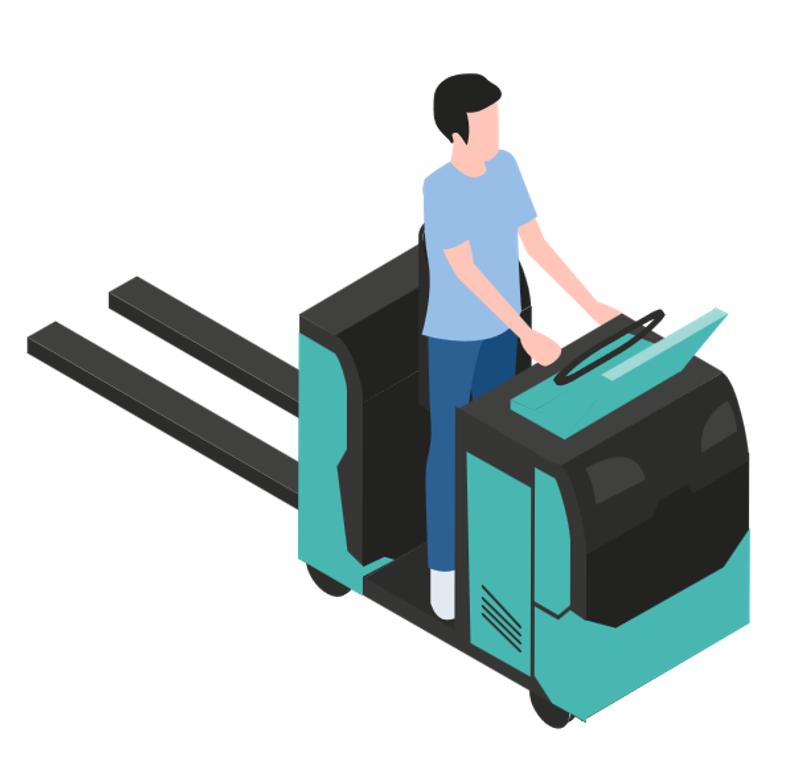

Rider High Lift Stacker

- Ergonomic and time-saving, especially for long distances

- Combination of lifting and driving for efficient pallet handling

- Suitable for a medium lifting height