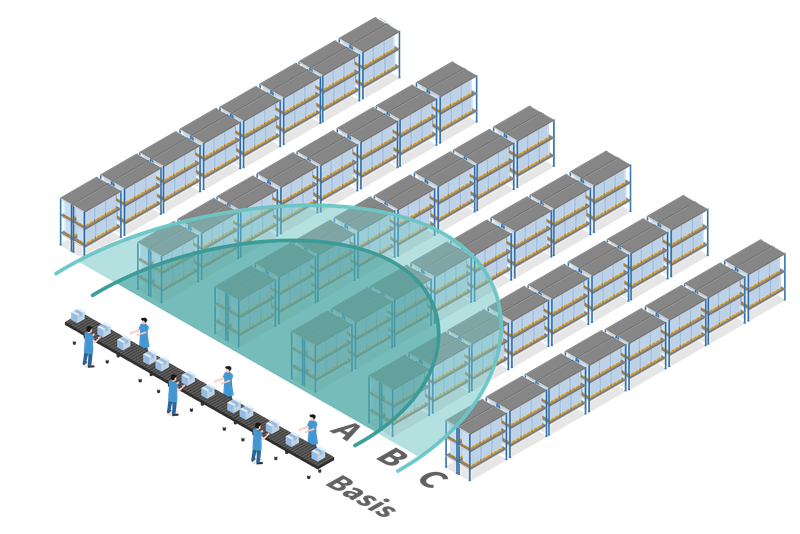

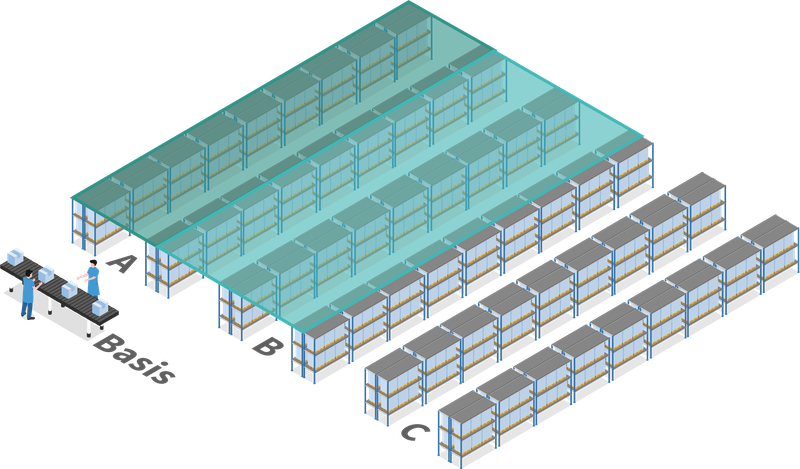

ABC Zoning in a stripe layout

The ABC method for reducing avoidable journeys

The ABC method basically describes the classification or grouping of all items in a product range according to their frequency of access. Based on this classification, items can be divided into three zones (ABC). The aim is to identify items with a high frequency of access, known as "fast movers" (A items), and place them as close as possible to the picking base. This saves long travel and walking distances to the items. "Medium-turnover" (B items) and "slow-turnover" (C items) are stored further away from the base station. The boundaries between ABC groups can be chosen freely, but it is advisable to use the Lorenz curve as a guide:

ABC Zoning in a stripe layout - Solves the following Problems!

Select one of the problems. You will receive instructions that you can use to calculate optimization potential.Long walking distances

Long Distances without Picks

Frequent Aisle Repetitions

Long Transport Distances

Long driving distances

ABC Zoning in a stripe layout - Find the Right Offering for You

Select products and receive detailed information. You can use the platform to contact product suppliersABC Zoning in a stripe layout - The Following Solutions can also Solve the Pain Point

Here you can find other solutions, which are suitable for the optimization of the pain points (Long walking distances) as well as variants of the current solution.

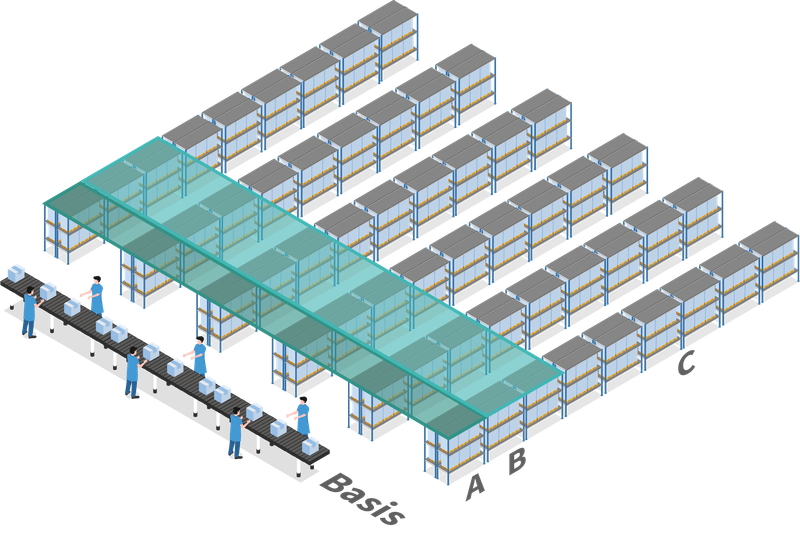

ABC zoning edge-based

- Distribution of articles according to access frequency

- Reduces walking time and congestion

- Prioritizes inventory

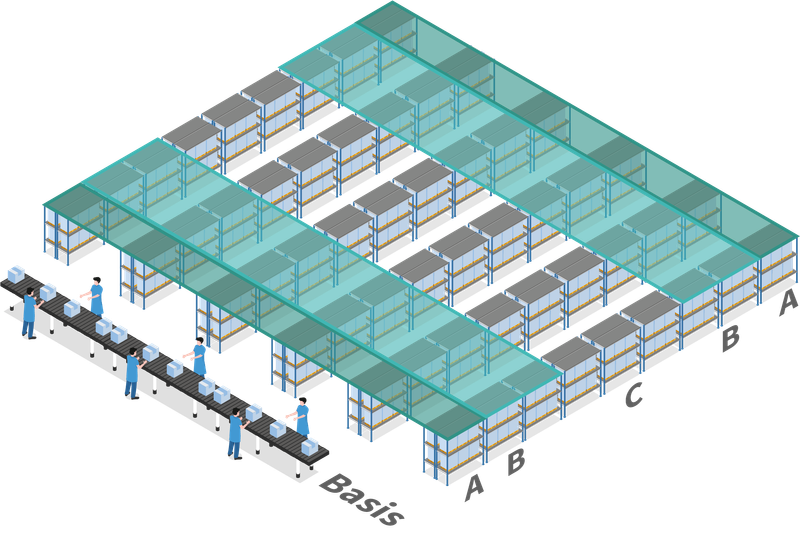

ABC zoning in a segment layout

- Distribution of articles according to access frequency

- Reduces walking time and congestion

- Prioritizes inventory

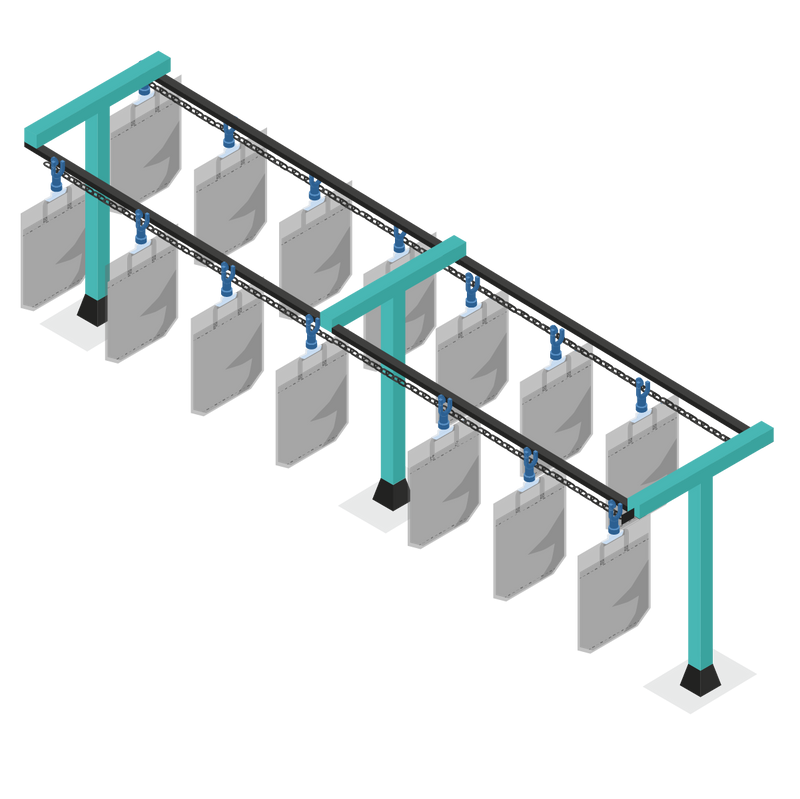

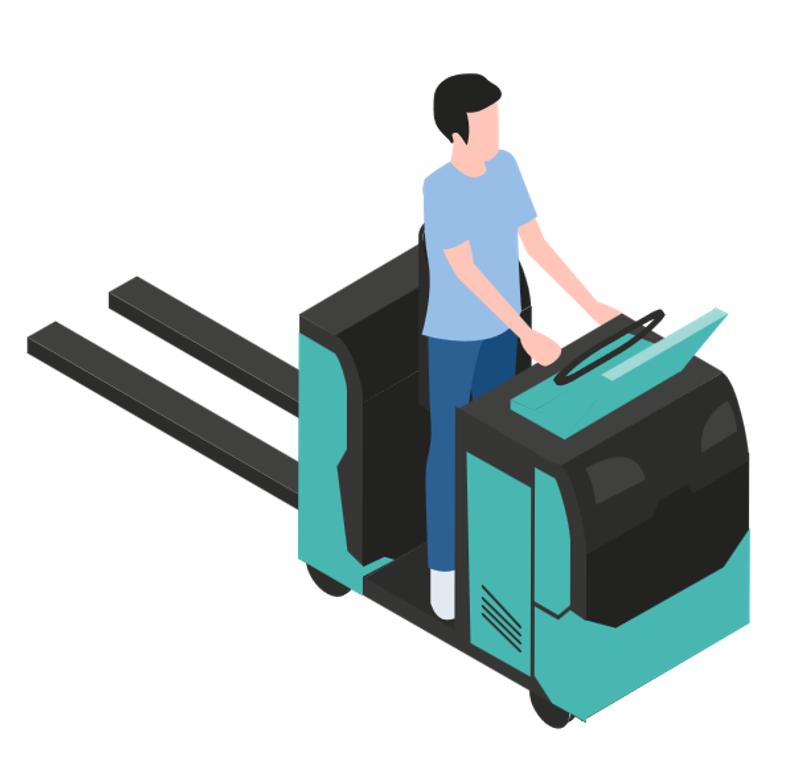

Horizontal Order Picker

- Efficient order picking at floor or low shelf levels

- Ride-on platform and long forks to increase production

- Automatic following system possible

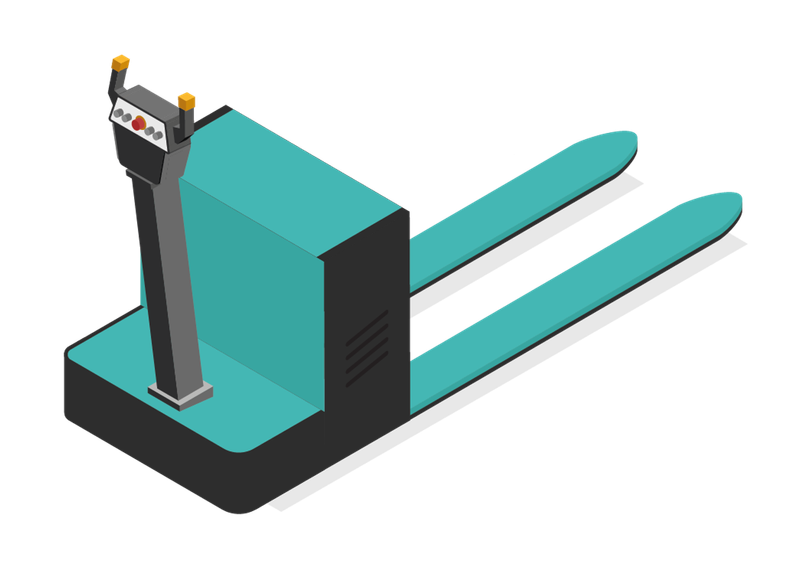

Pedestrian Pallet Truck

- Pallet truck with electric drive and escort on foot

- Effort-saving and ergonomic pallet truck variant

- Flexible application options in intralogistics

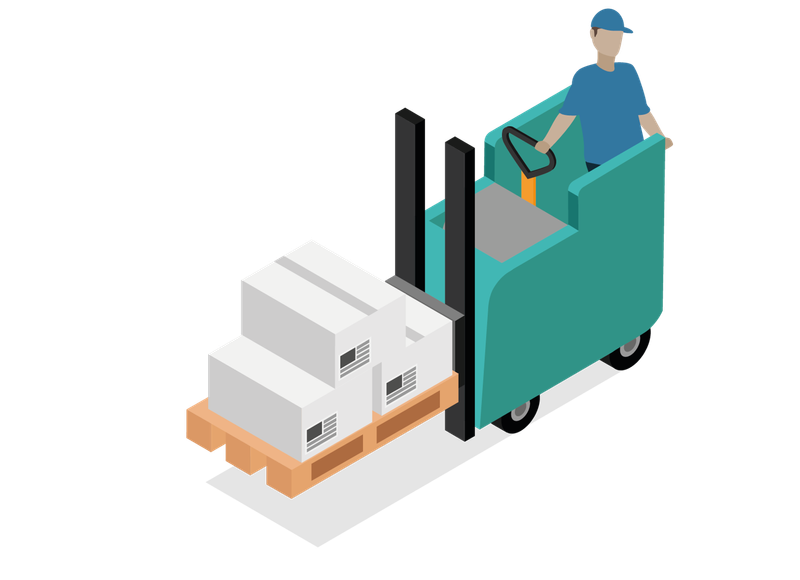

Rider High Lift Stacker

- Ergonomic and time-saving, especially for long distances

- Combination of lifting and driving for efficient pallet handling

- Suitable for a medium lifting height

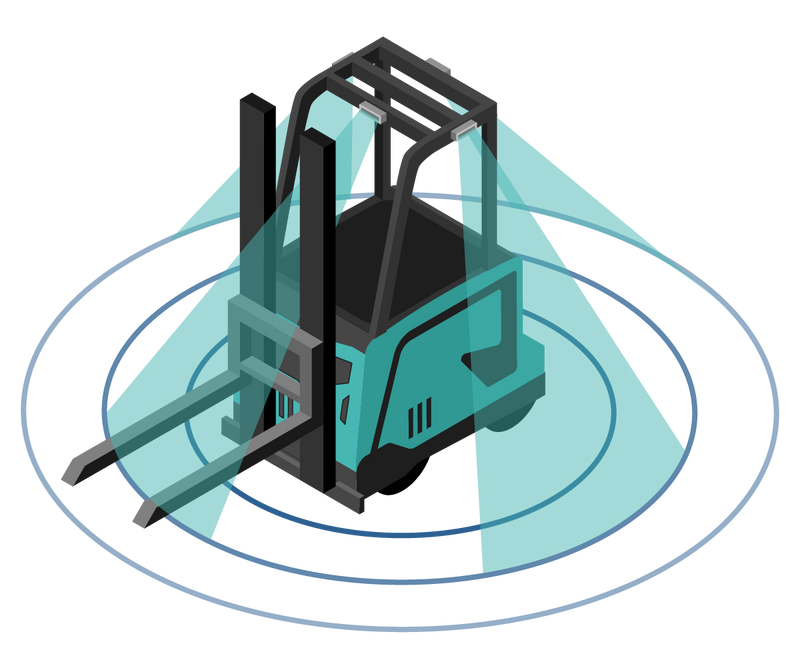

Forklift Truck – Autonomous

- Increased efficiency through continuous workflows

- Cost savings due to reduced personnel requirements

- Increased safety thanks to sensors