| Price from | On request |

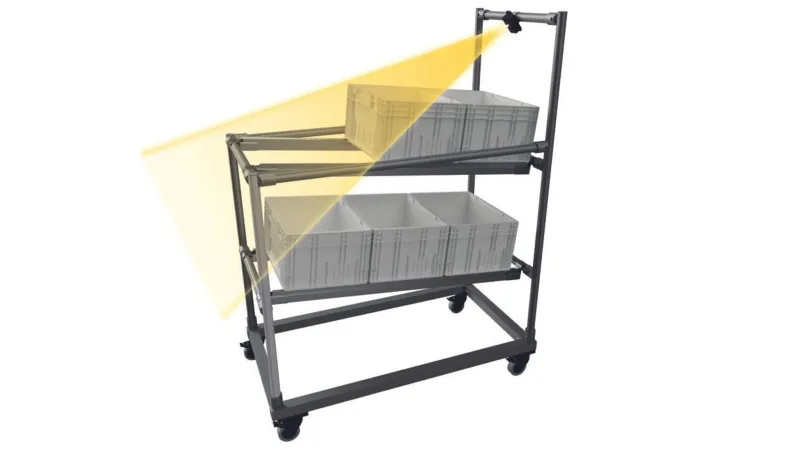

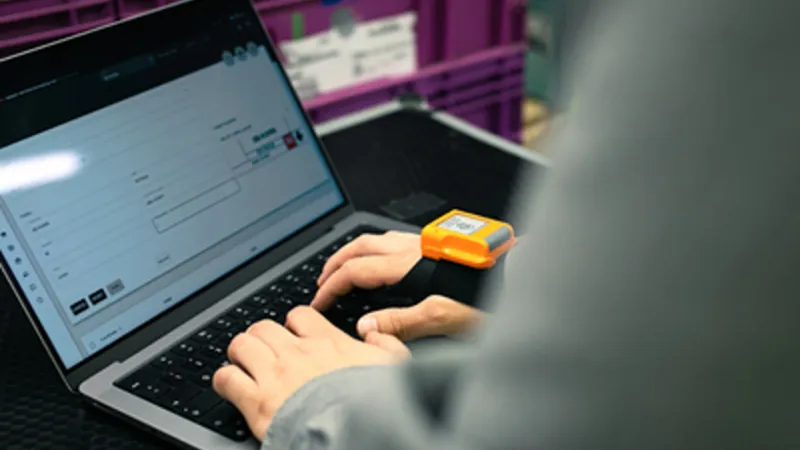

| Application reasons | Error reduction, Storage space & capital commitment, Planning optimization, Route & walking path optimization, Order processing & workflow optimization (Increased efficiency: Thanks to the automated ordering and replenishment process and the integration into the existing IT infrastructure (e.g. in the ERP system), nexy automatically recognizes when material needs to be reordered and how much - without any personnel or administrative effort. Cost reduction: The precise control of the material flow creates the conditions for a reduction in stock levels while at the same time ensuring high availability and security of supply. Error prevention: Incorrect orders are ruled out, as are gaps in the information and supply chain. The pull principle works consistently, the parts or containers can always be located precisely. A good basis for optimization. The real-time image of the material flow provides a good basis for the continuous optimization of processes.) |

| Type of solution | Software + Hardware |

| Software costs/ user licenses | Business license |

| Clients | Web browser |

| Supported operating systems | Linux |

OX-Kanban Sensor