Automatic Goods Receipt/Issue Booking vs. Pallet and Cargo Measurement

Two technologies, one goal: more efficient logistics processes. But how do they differ—and when is each solution the right choice?

In modern intralogistics, efficiency is driven not only by speed but also by transparency and process reliability. Two technologies currently in focus are:

• Automatic Goods Receipt/Issue Booking

• Pallet and Cargo Measurement

Both systems aim to reduce manual effort, minimize errors, and improve data quality. However, they address different process stages and follow distinct approaches.

This article outlines which solution fits which use case—and when combining both technologies delivers maximum value.

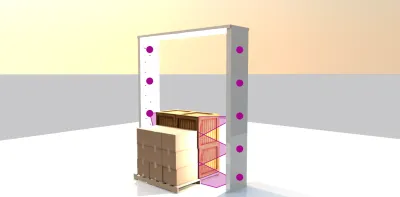

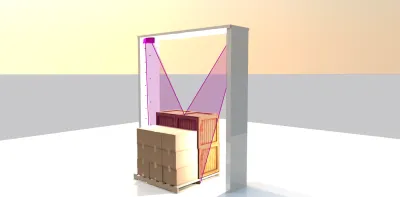

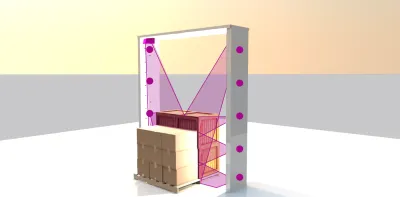

Automated measurement of a package in a logistics process.

Automated measurement of a package in a logistics process.What Does Automatic Goods Receipt/Issue Booking Deliver?

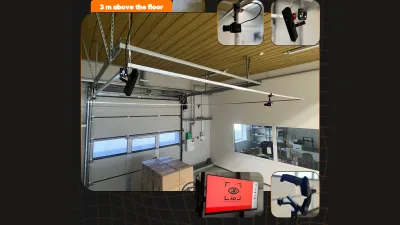

Automatic booking in goods receipt and issue replaces manual scanning and input processes with continuous digital capture. As soon as goods enter or leave the warehouse, the process is detected in real time and booked in the system—without any active intervention by employees.

Depending on infrastructure and requirements, various technologies are used:

These include, for example, RFID systems that automatically respond when passing reading points, cameras with image recognition functions, automatic barcode scanners at gates, or sensors that detect movements at defined handover points.

The major advantage lies in relieving operational staff. Manual scans, matching pick lists, or error-prone entries are eliminated—along with many typical sources of error in goods handling. At the same time, process reliability increases, as bookings can no longer be forgotten or executed incorrectly.

Companies also benefit from:

- Higher data quality in the inventory management system

- Accelerated throughput times in goods receipt and issue

- Improved traceability of goods movements

- A solid foundation for automated downstream processes

Especially in environments with high throughput and standardized processes, automatic booking can fully demonstrate its strengths and contribute to real relief in day-to-day operations.

Typical application areas:

- Goods receiving ramps

- Shipping lines

- Automated handover points (e.g., with AGVs/AMRs)

What Are the Benefits of Pallet and Cargo Measurement?

Pallet and cargo measurement systems automatically capture the exact dimensions and weight of load units such as pallets, cartons, or irregularly shaped goods. Technologies such as 3D cameras, laser scanners, or integrated floor scales are used, often directly integrated into conveyor lines or checkpoints.

As soon as an object passes through the detection area, the relevant data is captured in real time, validated, and transmitted directly to connected ERP or warehouse management systems (WMS). There, they can be used for various purposes, such as classifying freight goods, determining optimal storage locations, or calculating shipping volume.

Their benefit lies in the combination of precision, speed, and system integration. Incorrect estimates or incomplete shipping information are avoided, and a reliable data foundation for downstream logistics processes is created.

Typical advantages at a glance:

- Accurate determination of volume and weight, even for complex packages

- Reduction of overloading and misloading through clear guidelines for picking and shipping

- Better utilization of transport equipment and storage space through valid planning data

- Automated calculation of shipping costs, especially for volume-based tariffs

Precise measurement pays off especially in complex distribution centers or with variable freight structures, as it creates transparency, reduces error rates, and ensures smooth operations from goods receipt to goods issue.

Typical application areas:

- Goods receipt inspection

- Shipping preparation

- Returns processing

- Freight billing

Stronger Together: When Is the Combination Worthwhile?

Automatic booking primarily targets process acceleration and system integration, while measurement ensures data depth and physical validation.

Together, they offer a holistic solution that ensures both process and physical reliability.

Example benefits of the combination include:

- Automatic reconciliation of goods receipt with actual cargo (e.g., in case of deviations in package dimensions)

- Documentation for freight billing or damage cases

- Linking ERP and freight management data

- Automated storage location suggestions based on actual dimensions

Conclusion: Decision Based on Process Goal

There are various technical solutions available to improve the efficiency and quality of logistics processes. For instance, automated goods receipt and goods issue booking can be used to automate the booking process. This reduces the need for manual intervention and minimises sources of error. Pallet and freight measurement is ideal for recording and validating transport data as it provides accurate information about dimensions and weights. To optimise process quality and data depth, it is recommended that both technologies are used to ensure comprehensive and reliable data throughout the entire supply chain.

How can Motion-Mining® Support Goods Receipt/Issue Booking?

- Precisely capture current process efforts: With Motion-Mining®, it is possible to analyze in detail how much time is spent on manual booking of goods. For this purpose, process times at PC workstations as well as working time in goods receipt and issue outside of vehicles are evaluated.

- Compare actual and target times: By comparing actual and target times—e.g., with and without booking or scanning processes—inefficient workflows can be clearly identified. This transparent analysis forms the basis for targeted improvement measures and sustainable process optimization.

- Evaluate cost-effectiveness: The precise determination of reducible efforts provides a reliable basis for ROI calculation and shows from which point an automated solution becomes economically viable.

How can Motion-Mining® Support Pallet and Cargo Measurement?

- Identify additional rearrangement efforts: Motion-Mining® analyzes dwell times in trucks or storage aisles and thus reveals unnecessary rearrangement processes. These may indicate missing information about cargo size and can be significantly reduced through more precise measurement.

- Make clarification efforts visible: Motion-Mining® captures how often employees have to walk to offices or team leads. Such interruptions indicate clarification cases or rework. These can be minimized through automated cargo measurement.

- Evaluate cost-effectiveness: The savings potentials identified by Motion-Mining® provide a reliable basis for evaluating cost-effectiveness. The return on investment (ROI) of an automation solution can be calculated precisely and transparently based on concrete data.

-1-800x352.webp)

-800x352.webp)