1

Determine the Frequency of the Inventory Process

The first step is to determine how often inventory counts are performed by employees. As a rule, a distinction is made between two main types of inventory counts:

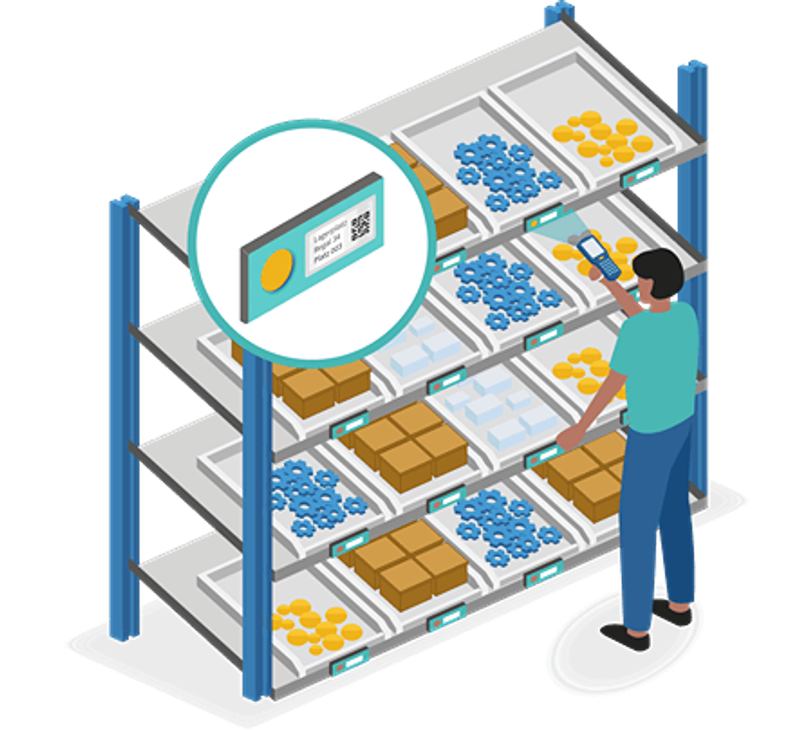

A

Permanent Inventory

In permanent inventory, inventory counts are performed continuously. In logistics, this happens, for example, through residual quantity or zero-crossing counts during picking. In permanent inventory, a small amount of work occurs very regularly. The frequency is usually stored in the WMS.

B

Closing Date Inventory

In the case of an annual inventory, the inventory is carried out on one day per year. The frequency is then usually one, but the one-time effort is comparatively high.

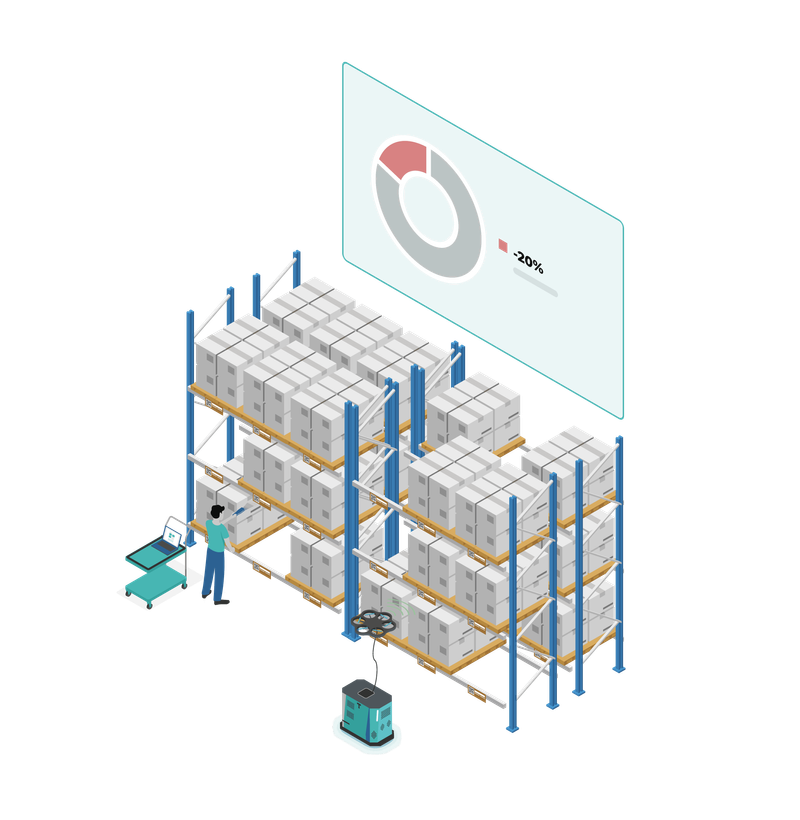

2

Determine the Effort of an Inventory Procedure

The effort of the inventory differs greatly depending on whether it is a cut-off date inventory or a perpetual inventory.

A

Permanent Inventory

With permanent inventory, process monitoring can be used to analyse how long it takes to enter the current quantity once or to confirm zero crossing.

B

Closing Date Inventory

For the inventory on the reference date, the working time of all employees involved in the inventory should be added up.

3

Determine Total Expenditure

The total effort equals the frequency multiplied with the duration of each task. In both cases, the time per worker and day should be extrapolated to the total hours per year.

4

RoI Calculation

In order to calculate the Return on Investment, it is necessary to determine what the optimised effort is for inventory activities. The optimized effort depends on whether the frequency or duration of the action is reduced. Accordingly, the calculation previously performed for the actual value must be performed again for the target value. The difference between the target and actual value gives the potential savings per year. This is compared to the cost of the activity.