Storage Solutions: The Foundation of Efficient Intralogistics

Introduction: Why storage solutions are more than infrastructure

Today, Storage Solutions determine far more than just “storage space.” They form the physical foundation for processes, automation, and efficiency—from manual to semi‑ and fully automated operations. The choice of the right system influences throughput, flexibility, and the long-term economic viability of a site. While material flows are visible, the underlying drivers of smooth operations often remain hidden: the layout, system logic, and the way goods are stored, staged, and moved.

Between inventory and movement: Storage Solutions create the structural basis for automated and resilient intralogistics.

Between inventory and movement: Storage Solutions create the structural basis for automated and resilient intralogistics.Core areas of storage solutions

Modern Storage Solutions consist of modular components that can be combined, with weighting varying by application scenario.

- Storage Solutions (Racking Systems): Pallet, shelving, and multi‑tier systems form the foundation of many warehouses. They offer simple integration, clear structures, and high flexibility—especially in brownfield environments.

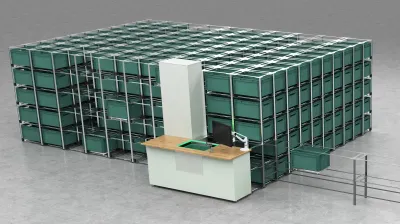

- Shuttle & Channel Storage Solutions: Ideal for high throughput and repetitive processes with standardized load carriers, offering high storage density and fast access.

- AS/RS (Automated Storage & Retrieval Systems): Automated small‑parts or pallet Storage Solutions maximize space utilization and process reliability. They require careful planning and integration.

- Conveyor Technology: The backbone of continuous material flows between storage areas, production lines, and picking stations, often used as a key lever for takt time and throughput.

- AGV/AMR‑Supported Storage Solutions: Combining traditional Storage Solutions with Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) enables highly flexible material flows without fixed conveyor infrastructure. They are particularly suitable for dynamic layouts, step‑by‑step automation, and brownfield facilities where scalability and adaptability are critical.

Trends & challenges in storage solutions

Decision-making is increasingly shaped by performance pressure, limited space availability, and cost sensitivity. Four developments stand out:

- Brownfield in Focus: As new space becomes scarce, automation of existing sites is gaining importance. Demand is rising for compact, modular systems that can be integrated without long downtimes.

- Flexible Automation: Rigid conveyor technology is being supplemented by scalable modules—for example shuttle systems, AMRs, and modular Storage Solutions. This enables adjustments during ongoing operations, provided process and system integration are well-designed.

- Software, Data & AI: Storage Solutions are closely linked to IT. Real-time data, cloud-based control systems, and AI-driven optimization influence material flow. Without stable IT and clear interfaces, the potential remains underutilized.

- Economics & Security: Investments are subject to strict cost-benefit scrutiny. At the same time, IT security, resilience, and sustainability are becoming increasingly important to ensure long-term robustness of storage structures.

Outlook: Storage solutions as a strategic lever

The future lies not in “maximum automation,” but in tailored, combinable, and data-enabled solutions aligned with real process requirements rather than idealized scenarios. Those who view Storage Solutions as a portfolio of scalable building blocks can quickly respond to demand changes, product variants, and layout adjustments.

Top Suppliers on MotionMiners SOLUTIONS

The most viewed suppliers in the field of storage solutions on our platform include:

Cellgo automates small-parts storage environments specifically for mid-sized businesses with a turnkey combination of robotics, software, and modular storage concepts. The solution is easy to integrate and flexibly expandable—even in brownfield settings.

MODULA stands for space-saving vertical Storage Solutions and complementary software/picking applications. Its global network and new site in Gersthofen ensure fast implementation and reliable operation.

Gridstore delivers tailored, highly flexible compact Storage Solutions for picking and buffer applications, emphasizing sustainability with energy-efficient PowerCaps and recyclable containers.

Jungheinrich offers end-to-end intralogistics solutions—from industrial trucks to fully automated system solutions—including software, service, and a dense spare parts/service network for maximum availability.

How does Motion-Mining® support the selection of the right storage solutions?

Selection is rarely purely technical. Motion Mining® provides an objective foundation by analyzing real paths, movements, and process times in existing operations. This reveals:

- Where Storage Solutions support or slow processes, e.g., through waiting times, detours, or rework.

- Which systems truly work in daily operations—and which only look good on paper.

This ensures Storage Solutions are selected based not on catalog assumptions, but on data—as the foundation of efficient intralogistics.

-1-800x352.webp)

-800x352.webp)