#DiscoverTheDifference: Excel is Not Load Carrier Management

Why transparency in everyday returnable packaging requires more than spreadsheets

“We have our load carriers under control – it all runs via Excel.”

This sentence comes up regularly in conversations with logistics managers. And it is understandable: there are spreadsheets, postings, monthly reconciliations, and experienced employees who know how things work. At first glance, it appears organized. But this is exactly where a common misconception in load carrier management begins.

Control through spreadsheets – and the assumption that Excel reflects reality

Excel is flexible, quick to set up, and available in every company. That is why it is often declared the central system for pallet, container, or rack accounts. Movements are entered, balances calculated, discrepancies commented on.

The problem: Excel does not reflect reality – it only reflects what someone documents afterward with significant time investment.

The reality: load carrier management is a circulation problem.

Load carriers are constantly moving: between plants, carriers, customers, suppliers, and exchange partners. That is exactly what makes them so valuable – and so difficult to control.

Dr. Philipp Hüning, Co‑Founder and CEO of Logistikbude – is shaping the transformation towards transparent and efficient load carrier management.

Dr. Philipp Hüning, Co‑Founder and CEO of Logistikbude – is shaping the transformation towards transparent and efficient load carrier management.The reality: load carriers move faster than any spreadsheet

Returnable load carriers are constantly in motion: pallets, CC containers, racks, or trays change locations, partners, and responsibilities – often several times a day.

As a result, everyday reality often looks like this:

- Postings are made with delays or not at all

- Pallet slips remain in trucks, warehouses, or offices

- Reconciliations take hours every week

- Discrepancies only become visible when they become expensive

The core problem is not a lack of discipline. It is a system that was not designed for operational logistics processes.

Excel can calculate, sort, and analyze – but it cannot capture movements, map responsibilities, or create real-time transparency.

The result: uncertainty instead of control. Reacting instead of managing.

The solution: capture load carriers where they are actually moved

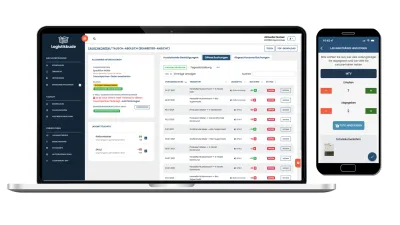

This is exactly where we come in as Logistikbude. Our solution approaches load carrier management from the operational day-to-day perspective – not from the desk. Instead of spreadsheets, lists, and retroactive maintenance, we create a platform that captures, documents, and makes load carrier movements transparent directly within the process.

Specifically, this means:

- Postings are created where load carriers are moved – in the warehouse, at goods receipt, during dispatch

- Pallet slips are captured digitally and processed automatically

- Inventories, balances, and discrepancies are available and up to date at all times

- Reconciliations with partners are handled in a structured way via web links instead of email

What makes our solution special

Many providers digitalize individual steps.

We digitalize the entire returnable packaging process:

- Process proximity instead of theory: Our software is not added “on top” but integrates into existing processes and systems (SAP, TMS, ERP, WMS, etc.) without unnecessarily complicating them.

- Automation instead of additional effort: Whether AI-based pallet slip recognition or automated postings, the goal is always to reduce manual effort – not shift it elsewhere.

- Transparency for all stakeholders: Internal teams, external partners, carriers, or customers. Everyone works on the same data basis – traceable and audit-proof.

- Scalable from start-up to enterprise: Our solution grows with requirements – whether a few locations or complex networks.

From a side process to tangible relief

At a logistics company, pallet management had long been handled via pallet slips and Excel. Reconciliations with carriers were time-consuming and error-prone. After switching to digital load carrier management, pallet movements could be captured directly in the process and reconciliations prepared automatically.

The result in daily operations:

- Around 50% time savings in pallet administration

- 100% real-time transparency

- Noticeably reduced repurchases

An example that shows: load carrier management is not a marginal topic. And Excel is not a necessary evil. The difference emerges where load carriers are understood and managed as an independent process.

Visit us at LogiMAT

You can find us in Hall 4, Booth 4A64, at the joint stand with S2data. On site, we will show you how digital load carrier management replaces Excel – and gives your team back up to two thirds of their working time in everyday returnable packaging operations.

#DiscoverTheDifference – Because we solve the most annoying process in logistics

About the author: Lisa Bornemann, Marketing Manager at Logistikbude GmbH