AMR vs. AGV: Which Solution Fits Your Intralogistics Needs

In-house transport logistics is increasingly becoming a bottleneck—especially in times of skilled labor shortages, growing product variety, and mounting efficiency pressures. Automated vehicles are therefore seen as a key technology in intralogistics. But which system offers the greatest benefits for your operations: Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs)?

This article outlines the key differences between AGVs and AMRs, their respective use cases, and how to determine the right solution for your specific requirements.

What Are AMRs and AGVs?

Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are two types of automated systems used in logistics and material handling. Both aim to streamline processes and boost operational efficiency.

AMRs are advanced robots that move autonomously within their environment and dynamically respond to obstacles and changes. They rely on a combination of sophisticated technologies such as high-precision sensors, powerful cameras, and complex algorithms to perceive their surroundings in detail. These sensors measure distances and detect nearby objects, while cameras capture visual data essential for navigation. The onboard algorithms process this data in real time to plan optimal paths and ensure efficient, safe movement through the workspace.

AGVs, on the other hand, follow predefined routes typically guided by magnetic strips, wires, or floor markings. These fixed paths provide a clear, unchangeable track for the vehicles to follow. Such physical guidance systems allow AGVs to move reliably within a well-defined area.

How Do AMRs and AGVs Differ in Practice?

At first glance, AGVs and AMRs perform similar functions. Both transport materials within a facility—automatically, reliably, and in a way that reduces the burden on human workers. However, they differ significantly in terms of navigation, flexibility, and required infrastructure.

AGVs operate on fixed routes defined by magnetic tapes, QR codes, or induction loops. These paths are predetermined, and any deviations—such as encountering unexpected obstacles—require manual intervention or predefined detours.

AMRs, by contrast, perceive their environment in real time using sensors, cameras, and intelligent algorithms. They plan routes independently and adapt dynamically to changing surroundings.

Direct Comparison of Use Cases

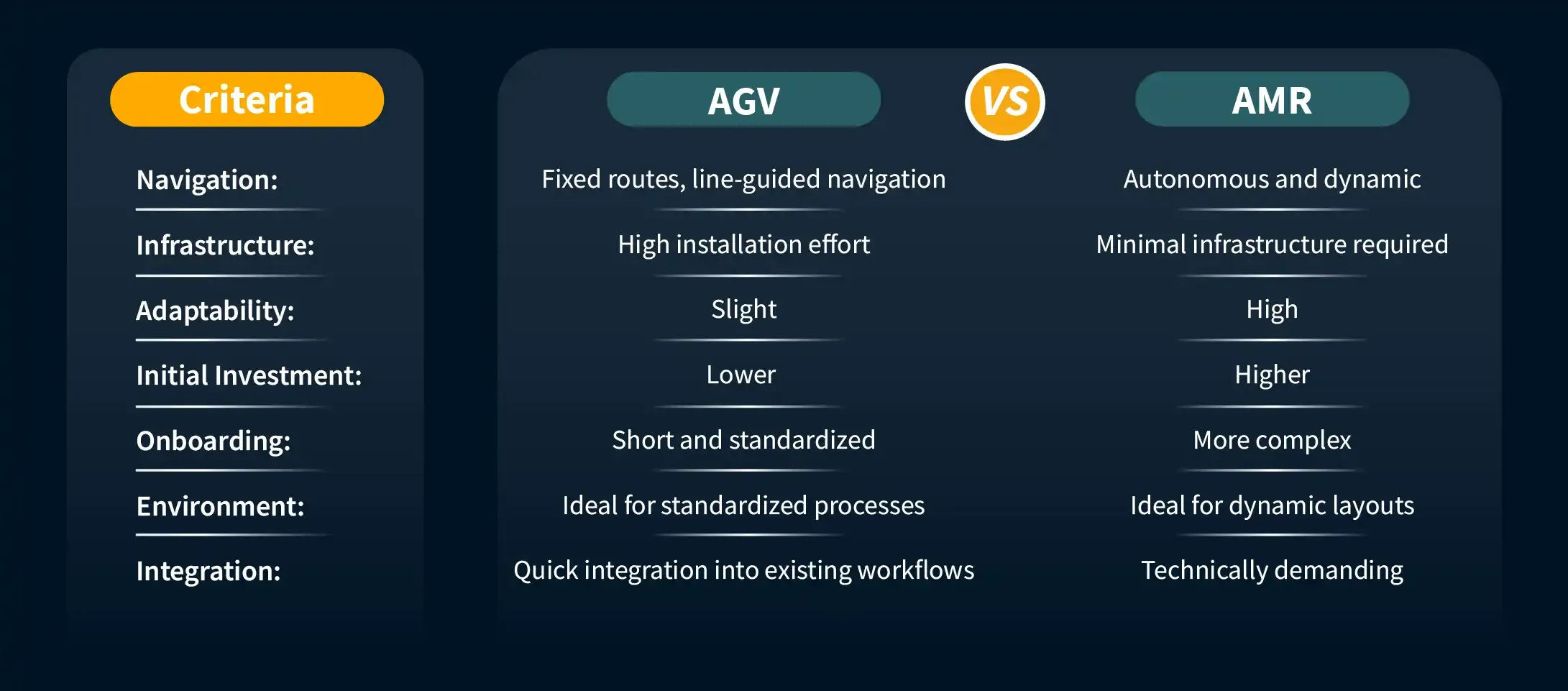

Comparison at a Glance: Key differences between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) in terms of complexity, infrastructure, and adaptability to dynamic environments.

Comparison at a Glance: Key differences between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) in terms of complexity, infrastructure, and adaptability to dynamic environments.What Are the Advantages and Disadvantages of AGVs?

AGVs stand out for their simplicity and cost-effectiveness, making them an attractive option for companies seeking a reliable automation solution. They typically come with lower upfront costs, as they do not require sophisticated sensors or advanced algorithms. This also translates into reduced maintenance costs due to their simpler design and operation. Their predefined paths offer consistency and predictability—advantages in stable and well-structured environments.

However, AGVs have limited flexibility and adaptability. In dynamic or rapidly changing environments, this can be a major drawback. Because they follow fixed routes, they struggle to respond to unexpected obstacles or environmental changes. As a result, manual intervention may be required, potentially causing disruptions and reducing overall logistics efficiency.

What Are the Advantages and Disadvantages of AMRs?

AMRs offer greater flexibility and adaptability. They are ideal for dynamic environments such as complex or frequently changing warehouses. AMRs can avoid obstacles and calculate alternate routes on the fly, increasing overall efficiency.

The downside lies in their higher purchase and maintenance costs due to the advanced technology and complex systems involved. These investments can be substantial, especially when a large fleet is needed. Additionally, operating AMRs often requires a more advanced infrastructure tailored to their autonomous functionality.

Which Technology Is Right for Your Business?

Choosing between AMRs and AGVs depends on your organization’s specific needs. A thorough analysis of your operational environment is crucial. If you're managing a dynamic warehouse, AMRs are likely the better fit. Their autonomous capabilities allow them to navigate complex spaces, respond to unexpected obstacles, and adjust routes efficiently.

For stable and predictable settings, AGVs offer a cost-effective solution. They are easier to deploy, operate on fixed routes, and are simpler to maintain—making them ideal for standardized processes with minimal variability.

How Can Motion-Mining® Support Your Decision?

Selecting between an Automated Guided Vehicle (AGV) and an Autonomous Mobile Robot (AMR) is a strategic decision with significant implications for the success of your intralogistics automation. Motion-Mining® provides a data-driven foundation that goes far beyond intuition and past experiences.

Make Flexibility Measurable:

Motion-Mining® technology captures whether your vehicles move along standardized, predictable paths or frequently deviate from main routes. These insights are essential: while AGVs are optimal for fixed transport paths, AMRs excel when frequent route adjustments are needed.

Analyze Performance Requirements Transparently:

By evaluating detailed motion data, we identify your main transportation routes and how often they’re used. These findings may yield unexpected insights—perhaps automating only a primary route is sufficient, while side routes remain manual, saving costs while improving efficiency.

Realistically Assess Vehicle Utilization:

Our measurement approach reveals how intensively your vehicles are actually used. This invaluable data helps determine the exact number of autonomous vehicles needed—avoiding over- or under-investment.

Justify Capital Investment Economically:

Motion-Mining® records route usage and intensity in detail. This forms the basis for solid ROI calculations: together, we determine when an AGV or AMR investment pays off and which option offers the best cost-benefit ratio.

Motion-Mining® transforms the AGV-vs-AMR decision from a complex trade-off into a transparent, data-backed choice—for automation solutions truly aligned with your logistics processes.

In what ways does MotionMiners SOLUTIONS support the selection process?

In addition to providing data-based analyses using Motion-Mining® technology, the MotionMiners SOLUTIONS platform supports the final system decision. It provides a comprehensive overview of over 100 AGVs and AMRs from various manufacturers, including technical specifications such as lift height, transport load and load carrier type. This is because, alongside process requirements such as flexibility and vehicle utilisation, structural and functional criteria are also important for selecting the right vehicle.

-400x201.webp)

-1-800x352.webp)

-800x352.webp)