5 Questions, 5 Answers: Tobias Ludwig from SimPlan on Logistik Solutions

How do simulation and digital twins help to understand, optimize, and future-proof complex logistics processes?

In the latest episode of our podcast “Logistik Solutions – 5 Questions, 5 Answers”, we talk with Tobias Ludwig, Authorized Officer at SimPlan Integrations GmbH, about the role of simulation, emulation, and digital twins in logistics and production. He shares fascinating insights into how data-driven process optimization works and why simulation has become an indispensable tool for planning and securing future logistics systems.

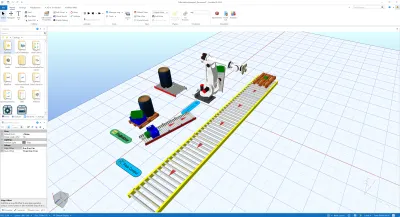

-2.webp) Tobias Ludwig from SimPlan demonstrates how simulation and emulation are transforming planning and enabling companies to make secure, data-driven decisions.

Tobias Ludwig from SimPlan demonstrates how simulation and emulation are transforming planning and enabling companies to make secure, data-driven decisions.Listen to the episode here or continue reading the blog to find out the answers to the five key questions.

Simulation Meets Reality: Planning with Foresight

SimPlan supports companies from the concept phase through to process optimization, using simulation and emulation to make workflows transparent and reveal hidden potential.

“While a simulation creates a virtual world, emulation connects real software with a simulated environment. That’s a decisive advantage for testing new systems under realistic conditions.” – Tobias Ludwig

This approach allows logistics facilities and IT systems to be tested, expanded, or adapted without interrupting real operations. It reduces risks, saves costs, and shortens project timelines—a critical factor in times of increasing automation and shorter innovation cycles.

Data Quality as a Success Factor

A key topic in the conversation: the quality of input data.

“Every model is only as good as the data it’s fed with.” – Tobias Ludwig

He emphasizes that valid data is the foundation of every successful simulation. This is where an exciting link to Motion-Mining® emerges: combining real process data from motion tracking with virtual simulation models creates an accurate representation of logistics workflows. This connection enables realistic scenarios, informed optimization decisions, and sustainable performance improvements.

Simulation as a Driver of Digital Transformation

Tobias also provides a glimpse into future developments: automation, AI-driven planning, and the integration of simulation into digital platforms will become increasingly interconnected.

SimPlan is already working on linking emulation systems with artificial intelligence. The goal: to use simulation to develop self-learning systems that can generate optimization proposals based on historical data and simulation results.

“Our goal is to safeguard our customers’ investments and make logistics as smart as possible.” – Tobias Ludwig

This makes one thing clear: simulation is not just a planning tool—it’s a cornerstone of digital transformation in logistics.

With his experience, Tobias demonstrates that data-driven planning is no longer a future topic; it already determines whether a project succeeds or becomes a costly misstep.

An inspiring conversation for anyone looking to make logistics more efficient and intelligent.

.webp)

-1-800x352.webp)

-800x352.webp)