5 in 5 with Maurice from Clover Optimization

In the latest episode of our podcast “Logistics Solutions – 5 Questions in 5 Minutes”, we welcome Maurice Morabel from Clover Optimization. He discusses the benefits of AI-powered transportation planning, which reduces driving distances, optimizes vehicle utilization, and significantly lowers transportation costs. With innovative solutions, Clover helps logistics companies automate and improve their route planning, lowering costs, reducing CO2 emissions, and increasing resilience.

Maurice Morabel from Clover Optimization discusses the benefits of AI-driven transport planning in logistics.

Maurice Morabel from Clover Optimization discusses the benefits of AI-driven transport planning in logistics.Listen to the episode here or continue reading the blog to find out the answers to the five key questions.

1. Briefly describe your company and product.

Clover is a technology provider based in Dresden, specializing in AI-powered transport planning for logistics fleets. Our software reduces driving distances, optimizes vehicle utilization, and significantly lowers transport costs. Since it integrates seamlessly into existing systems, users can implement it with minimal IT expertise—making it more accessible than ever.

2. What Problem do you solve?

We reduce complexity and relieve resource pressure in the logistics industry. Logistics companies face immense cost pressure, a shortage of drivers, and growing sustainability demands. Many still rely on manual or rigid route planning methods, leading to inefficient routes, empty runs, and high costs.

Our software empowers dispatchers to make not only faster decisions—but smarter ones. We're talking about up to 8x higher gross margins, reduced CO₂ emissions, and more resilient, less stressful planning processes for everyone involved—from dispatch to the loading dock.

3. What are your USPs?

We stand out both technically and culturally—two aspects that are deeply interconnected:

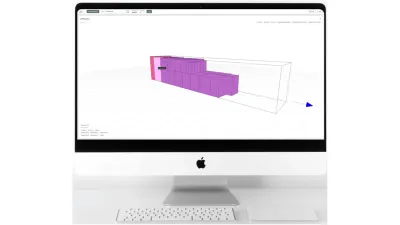

From a technical standpoint, route planning and loading planning traditionally occur in separate steps that need to be synchronized. Clover takes a completely new approach by analyzing everything in one integrated step—in just seconds. This leads to much better results and greater reliability, which in turn boosts user acceptance.

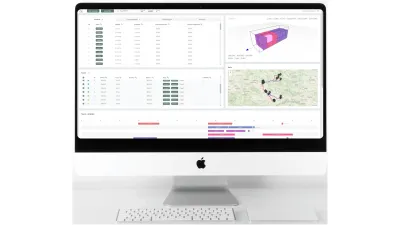

And on the cultural side: Many current tools fail because they deliver impractical results to dispatchers—essentially a "take it or leave it" approach. We integrate the expertise of dispatchers directly into our system, generating multiple planning scenarios that flow back into the TMS, WMS, or FMS.

The result? We don’t offer a purely mathematical optimum—we deliver a realistically executable one. This not only creates value from day one but also significantly outperforms conventional approaches—technically, culturally, and financially.

4. Provide a concrete use case or success story that illustrates how your solution works in practice.

Our customer base is diverse, making it hard to pick a single perfect example. We’ve worked with FTL, LTL, general cargo, parcel delivery, furniture logistics, even passenger transport—across fleets ranging from 10 to 1,700 vehicles.

Here’s a relevant example: A mid-sized freight forwarder from North Rhine-Westphalia, operating partial loads with 50 trucks (10 subcontractors), managed by four dispatchers. We integrated directly into their current TMS planning interface, so employees received optimized routes in their familiar environment. The integration took just one week—two with fine-tuning and feedback. Dispatcher training followed, though the system is largely self-explanatory.

Since implementation, the company has reduced driving distances by 26%—with the same shipment volume. That’s roughly a quarter less fuel and emissions. Planning time has also been cut by 3–4 hours daily. That’s a big win.

5. What future developments or trends do you see in the logistics industry and how are you preparing as a company?

Major societal shifts are impacting logistics as well.

Sustainability and emissions regulations will continue to challenge the sector. Fortunately, saving fuel is both an economic and ecological priority for the industry.

Automation and AI-driven planning are advancing fast. We're witnessing a leap forward compared to technologies from 10–20 years ago. Recent research breakthroughs are now making their way into the business world. Given the demographic shift and shortage of skilled talent, it’s crucial to empower existing teams with the right tools.

Flexibility and real-time optimization are also becoming more important. Supply chains are increasingly volatile, and businesses need to respond quickly to disruptions like traffic, weather, or demand fluctuations. Real-time adjustments increase both agility and resilience.

At Clover, we see ourselves as a technological frontrunner, especially when it comes to supporting mid-sized logistics providers with practical, forward-looking solutions.